From Toolmaker to Tooling Integrator: Plyable’s next chapter

Executive summary

Plyable began as a small-scale, low-technology tooling supplier. Initially focused on delivering simple tools quickly and cost-effectively during a time when tooling was an unavoidable cost rather than built into a strategic plan, Plyable established it’s relationship with key players whilst developing a unique proprietary AI software.

Over the past 7 years however, the industries Plyable serves have changed fundamentally. Aerospace, defence, automotive, marine, and advanced air mobility (AAM) programmes are becoming more complex, regulated and tightly constrained by quality, repeatability, and schedule risk. In this environment, the limitations of traditional toolmaking are increasingly exposed. From a technology push perspective, there are many new developments that need to be integrated into a tooling system, such as in-tool heating and 3D printing.

Outside of tooling itself, advances in automation, digital manufacturing, and data-driven engineering mean that tooling design and delivery must evolve. Tooling can no longer sit behind the curve of production technology, it must take centre stage and lead it, to ensure that all these advances are enabled.

Plyable has recognised a growing need in the market: not just for toolmakers, but for tooling integrators. Organisations capable of bringing together the right technologies, engineering disciplines, and delivery frameworks to manage tooling as a system rather than a standalone artefact.

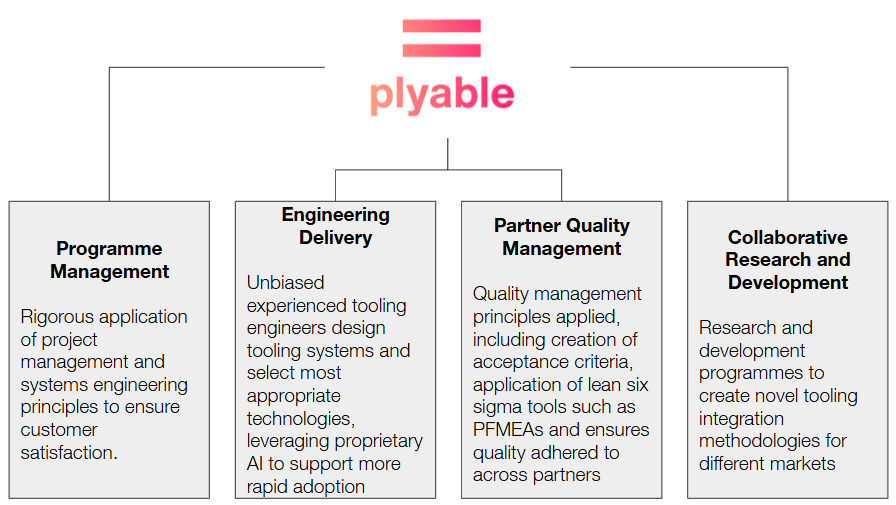

By combining Plyable’s AI technology, an expanded network of specialist technology partners, systems engineering principles, structured project management, robust quality frameworks, deep engineering and Lean Six Sigma expertise, Plyable is becoming a leading tooling integrator player. This whitepaper explains why traditional toolmaking models are no longer sufficient, what tooling integration means in practice, and how Plyable’s next chapter is focused on delivering higher-value, lower-risk tooling solutions for complex manufacturing programmes.

1. The changing role of tooling in Advanced Manufacturing

For much of its history, tooling has been viewed as a secondary consideration in manufacturing programmes. It was typically framed as a necessary cost, something that generally was specified late, procured quickly, and optimised primarily for price and lead time.

In this context, success was measured narrowly: did the tool arrive on time, and did it broadly conform to the required geometry? A common pattern with this approach of pursuing “fast and cheap” solutions early, usually followed by escalating effort and cost later. Early-stage decisions are optimised for speed and price, while downstream teams are left to manage the consequences.

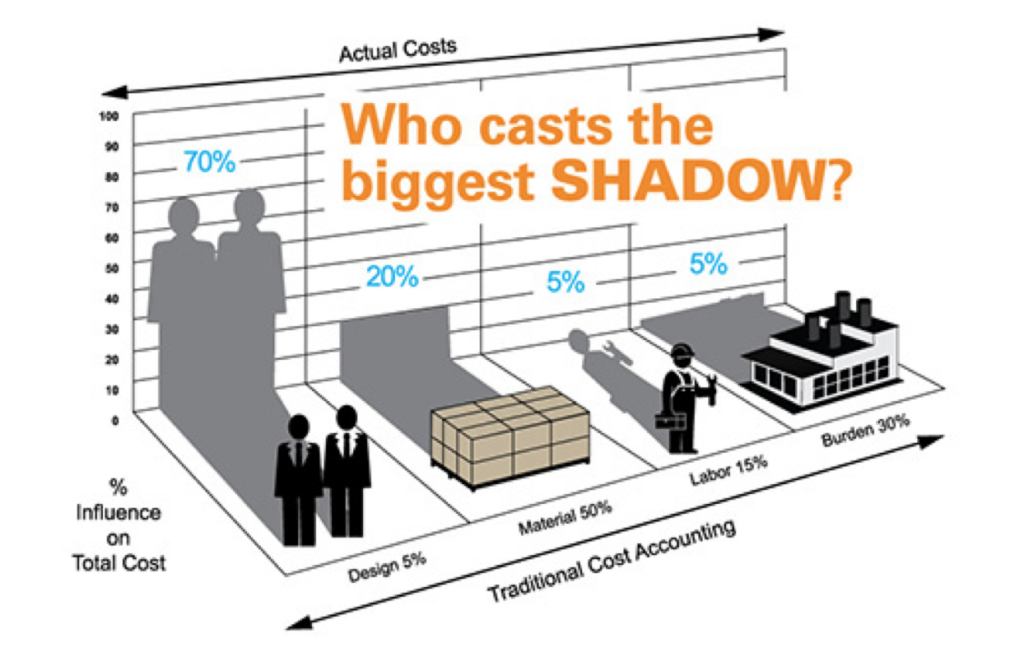

This dynamic reflects what is sometimes described by the concept of “who casts the biggest shadow.” By the time tooling and production is considered during the development process, many times part design has already been frozen, making tooling more challenging and less easy to optimise the process. With the large numbers of different tooling options now available, along with new process technology (whether physical automation or digital technology requiring sensors to be embedded into the tooling), there is also a high risk that the “fast and cheap” approach also means that the tool that is ultimately delivered is not fit for purpose. This dynamic is exacerbated by the presence of “unknown unknowns”, that is risks that remain hidden because they fall between organisational and contractual boundaries.

Across aerospace and adjacent industries, manufacturing programmes have become significantly more complex. Several trends are driving this shift:

- More demanding product architectures with tighter tolerances, complex geometries, and multi-material assemblies

- Advanced manufacturing processes including automated composite layup, high-temperature curing, precision forming, and hybrid manufacturing routes

- Greater reliance on automation and robotics, where tooling must interface seamlessly with machines, sensors, and software systems

- Longer programme lifecycles, requiring tooling to remain stable, repeatable, and maintainable over many years

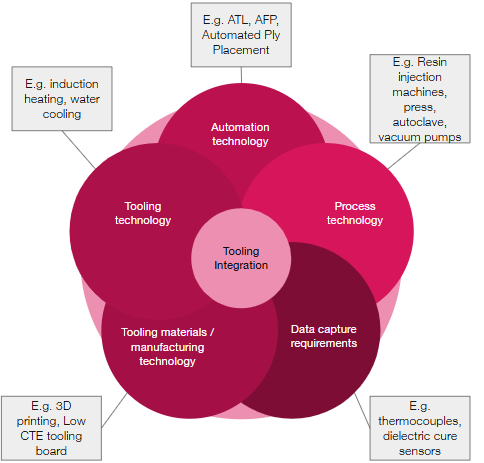

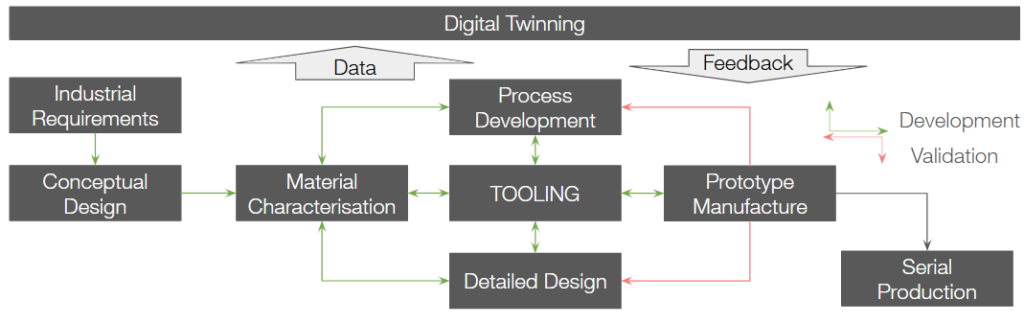

In this context, tooling is not a passive enabler. As shown in the diagram below, tooling acts as the focal point to enable many different parts of the manufacturing process. It actively shapes manufacturing capability. Poor tooling decisions can constrain process capability, introduce variability, and limit the effectiveness of automation – often in ways that are difficult or impossible to correct later.

This changing role of tooling demands a corresponding change in how it is conceived, designed, and delivered. Modern programmes require tooling to be:

- Engineered as part of a system, not as an isolated artefact

- Designed with full lifecycle visibility, from concept through production and change

- Integrated with manufacturing, quality, and automation strategies

- Governed through structured, traceable engineering processes

This shift represents a move away from tooling as a transactional purchase and towards tooling as a strategic capability. It is this shift that underpins the concept of tooling integration and why it has become essential rather than optional in advanced manufacturing environments.

2. The limits of the traditional toolmaker model

Toolmakers are highly skilled in the design and manufacture of individual tools using specific technologies, however as the technologies mentioned in the previous section are being developed and adopted by OEMs and tiered suppliers, the tool maker model itself is increasingly misaligned with the demands of complex, system-driven manufacturing. Traditional toolmakers are generally experts in the tool itself: materials, construction methods, and fabrication techniques. However, they are often less deeply integrated into:

- The behaviour of the full manufacturing process

- The interaction between tooling, automation, and inspection systems

- The operational realities of production environments

As a result, tooling is frequently designed to meet nominal requirements rather than actual process capability. Interfaces with equipment, sensors, and quality systems may be assumed rather than engineered. An unbiased tooling integrator is required to ensure the correct tooling technology is utilised for the application at hand, and the skills and experience of the toolmakers using the correct tooling methodology is leveraged.

The core limitation is not capability, but fragmentation leading to siloing. In a conventional tooling model, responsibilities are divided across discrete phases such as:

- Tooling design is completed, often with limited input from manufacturing or quality

- Manufacture is focused on delivering geometry to drawing

- Validation and inspection are treated as downstream activities

- Production support is reactive, provided only once issues arise

As a result, tooling is frequently designed to meet nominal requirements rather than actual process capability. While this may be an extreme example, interfaces with equipment, sensors, and quality systems may be assumed rather than engineered.

Each phase is typically optimised in isolation. Handover points introduce assumptions, interpretation, and loss of intent. Critical decisions made early are rarely revisited with full system context as new information emerges. This fragmentation creates gaps that are invisible at the outset but costly later. These gaps rarely surface during design review. Referring back to diagram 1, they emerge during build, qualification, or early production when change is most disruptive, and can manifest as:

- Late design changes driven by manufacturing or inspection constraints

- Tolerance stack-up issues identified only after tool build

- Weak documentation and traceability, complicating qualification and audit

- Rework and delays that push tooling onto the critical path

Individually, these issues may appear manageable. Collectively, they represent systemic risk. As complexity, automation, and regulatory pressure increase, these risks and their consequences become more pronounced. Addressing them requires more than incremental improvement but a fundamentally different way of approaching tooling. This is the context in which tooling integration emerges: not as an enhancement, but as a necessary evolution.

3. What is Tooling Integration?

Tooling integration is an engineering-led approach that treats tooling not as a standalone deliverable, but as a system that spans design, manufacture, validation, and lifecycle support.

It recognises that in complex programmes, particularly aerospace, automotive and defence, tooling performance directly influences quality, schedule, cost, and programme risk.

Unlike traditional models where tooling design, manufacture, and qualification are handled in isolation, tooling integration brings these disciplines together under a single, coherent engineering framework using systems engineering thinking. Understanding tooling as part of a wider production system includes:

- The relationship between the tool and part geometry

- The interaction between materials, processes, and tolerances

- Requirements for inspection, repeatability, and requalification

- Realities of production use, maintenance, and change

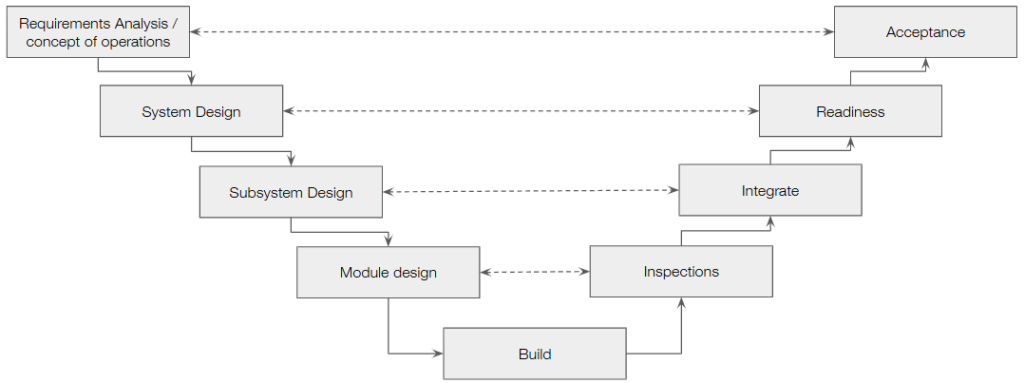

Systems engineering is an interdisciplinary, life-cycle–oriented approach to developing complex systems that emphasizes holistic system behaviour over isolated component optimisation. It is driven by structured requirements management, with traceability from stakeholder needs through design, implementation, and verification. The discipline integrates multiple technical and organizational domains using defined system architectures and interfaces to manage complexity.

Design decisions are informed by formal trade-off and risk analyses that balance performance, cost, schedule, and uncertainty. Continuous verification and validation ensure the system is correctly built and meets its intended operational objectives. Treating tooling as a system allows risks to be identified and addressed early when they are cheapest and easiest to resolve, and for Plyable, this manifests in the use of the Vee-model in Diagram 3.

Systems thinking is central to tooling integration which reduces late-stage surprises and supports predictable programme outcomes. Engineers must consider how decisions in one area affect the entire lifecycle of the tool. Examples include:

- Designing geometry and interfaces with other systems, inspection and repeatability in mind

- Selecting materials and construction methods based on thermal, structural, and durability behaviour

- Anticipating configuration changes and defining how they will be managed

Tooling integration is not simply offering design, manufacturing, and inspection under one roof. Bundled services often remain sequential and siloed. Design is completed, handed over to manufacturing, and then passed to quality for validation. Each handover introduces assumptions, delays, and opportunities for misalignment.

Integration, by contrast, is characterised by:

- Shared ownership of outcomes across disciplines

- Continuous feedback between design, manufacture, and validation

- Decisions made with full visibility of downstream impact

- A single point of accountability for tooling performance

4. Plyable’s evolution: from Toolmaker to Integration Partner

Plyable’s origins as a toolmaker provided foundations in engineering expertise, responsiveness, and practical problem-solving. Since working on major aerospace and automotive programmes however it’s become evident that there’s a growing need for clients to find innovative collaboration partners who are able to integrate their tooling solutions within legacy or expansive corporate manufacturing systems.

Suppliers and tooling technology developers also need opportunities and routes to market for their individual products and services to be more widely known with the potentially integrated into corporate systems.

Several puzzle pieces were already in place:

- Plyable’s proprietary AI tool developed using extensive tooling and manufacturing data to provide immediate feedback on tool designs, costs and lead times.

- Broad experience across industries and processes.

- Strong engineering fundamentals.

The decision was made to evolve. This evolution has meant:

- A new senior leadership team, including a CEO with experience running programmes in large aerospace organisations, a Head of Quality qualified as a Six Sigma Black Belt, a Technical Director with over 30 years’ experience across multiple tooling processes and a Sales Director with an aerospace innovation and R&D background

- Restructuring of the business operating model to implement systems engineering and programme engineering frameworks, primarily the Vee-model shown in diagram 3, strengthened project management through milestone-based design reviews, and placed quality at the centre of every programme. Process mapping tools such as PFMEAs and value stream mapping are now standard, supported by lessons-learned logs to ensure continuous improvement.

- Partnerships with research and technology organisations (RTOs) and specialist technology developers further expand Plyable’s integration capability, supported with collaborative R&D projects.

In complex tooling programmes, design decisions carry the greatest leverage over risk, cost, quality, and delivery performance. Choices made at the design stage define not only what a tool looks like, but how it behaves throughout its entire life. Once a tool enters manufacture, the opportunity to influence outcomes narrows rapidly. Late changes become expensive, disruptive, and often compromise downstream processes. For this reason, tooling integration succeeds or fails at the design phase.

The conceptual design phase is where Plyable’s AI can provide significant value. AI technology that can analyse part models, generate preliminary mould designs, and provide immediate feedback on cost and lead time fundamentally changes the way early-stage tooling decisions are made. Rather than relying on a small number of manually generated concepts, engineering teams can rapidly explore a much broader design space, comparing alternative materials, construction methods, and process assumptions in near real time. This capability accelerates conceptual trade-off studies, allowing many more iterations to be evaluated within the same timeframe and making the impact of design choices visible much earlier in the programme. By shifting effort to the front end of the lifecycle, AI-enabled tools support better-informed decisions, reduce reliance on late-stage optimisation, and increase the likelihood that the selected tooling concept represents a genuinely optimal balance of performance, cost, lead time, and risk.

Plyable’s AI tools are designed to support engineering judgement, not replace it. The AI is used to:

- Identify potential risk areas early in the design phase

- Support trade studies by exploring design options and constraints

- Highlight patterns and lessons learned from historical data

- Improve repeatability by reducing reliance on undocumented tribal knowledge

Final decisions remain with experienced engineers. The AI provides insight and visibility, not automated answers. Using the technology, Plyable’s engineering team can engage with development programmes at any point from initial requirements through to serial production to provide the most appropriate tooling for the application, considering materials, process, design and production requirements, summarised in diagram 5 below (Reference: Stojkovic, Miroslav & Butt, Javaid. (2022). Industry 4.0 Implementation Framework for the Composite Manufacturing Industry. Journal of Composites Science. 6. 258. 10.3390/jcs6090258.)

Customers should expect:

- Clear accountability

- Integrated engineering and delivery models

- Structured quality and project management frameworks

- Early engagement and transparent communication

Working with Plyable means engaging early, defining requirements clearly, and collaborating throughout the tooling lifecycle.

Plyable’s engineering team, combined with its AI can:

- Identify potential risk areas early in the design phase

- Support trade studies by exploring design options and constraints

- Highlight patterns and lessons learned from historical data

- Improve repeatability by reducing reliance on undocumented tribal knowledge

- Leverage tribal knowledge held across many partners to ensure that the knowledge is not lost and continues to be used.

- Deliver optimised toolsets from simple prototype tooling, through toolsets with significant quantities of tools, to highly complex, digital tooling for the next generation of aircraft, automotive or other platforms.

Tooling integration will continue to evolve alongside digital manufacturing and AI-enabled engineering. Plyable’s vision is to use these tools to create integrated, high-value tooling solutions that support the future of manufacturing.

Plyable is committed to engineering-led partnerships and early engagement. For organisations facing complex tooling challenges, the next chapter starts with integration.

Date published: 09.01.2026

Written by Jamie Snudden

Wish to speak to us about a project?

Fill out our contact us form, we will always aim to get back to you on the same working day

Book in directly with Sales

info@plyable.com | 01865 686164

Joshua England – Global Sales support

Stay connected.

Follow us on LinkedIn or sign up to our marketing newsletter.

- See our latest projects first

- Connect with our expert team

- Access deals and promotions

”Great communication, the website was very good and allowed easy sharing of files & communication.

The team were a great help and ultimately designed us a fantastic tool”

-Automotive client, July 2025