Design for Manufacture (DFM)

Our software automatically carries out DFM analysis on any molds that you upload. This analysis is built on our extensive real world engineering knowledge to highlight any possible areas that could be improved on in your mold.

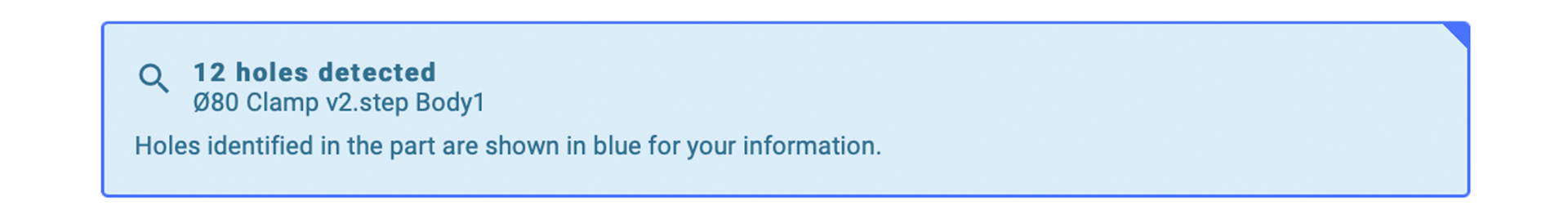

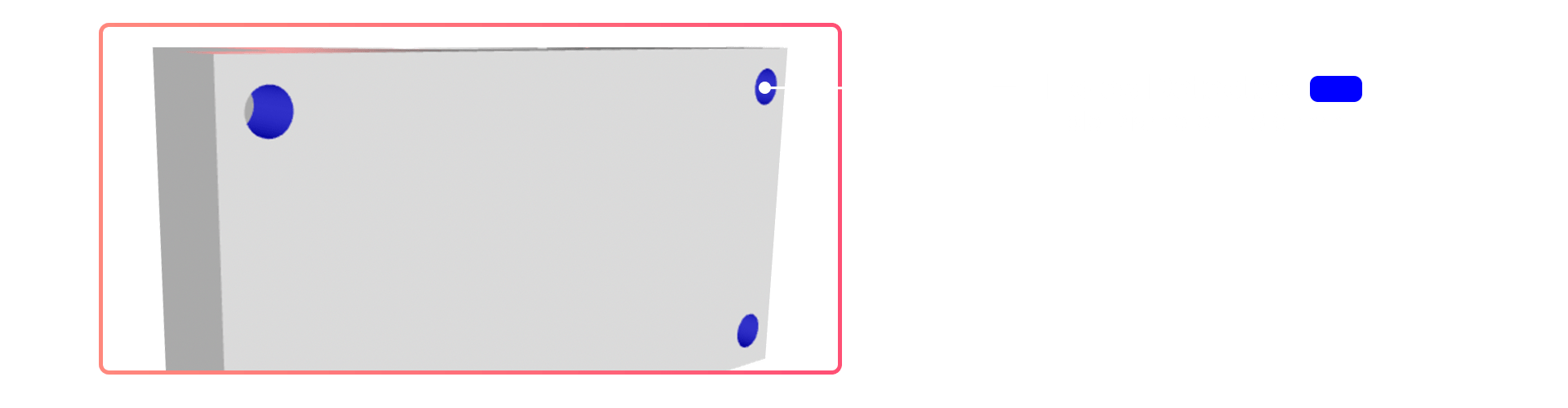

Hole Detection

Holes that can be drilled out of the part are detected and displayed, along with their diameter.

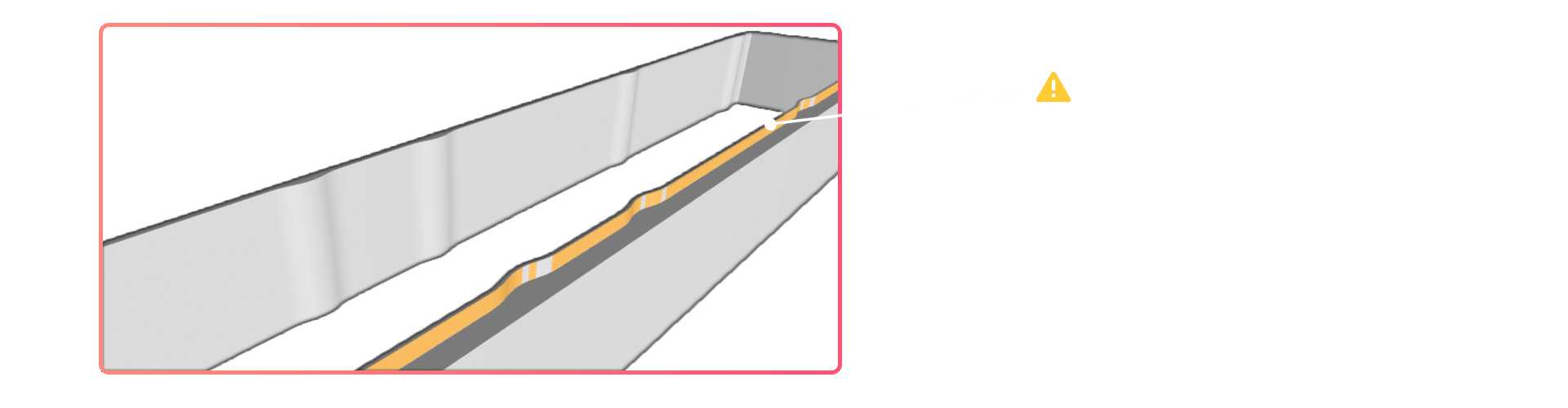

Thin Walls Detection

Thin walls can break during the molding process and increase costs. Our software automatically detects these regions and highlights them for the user. Our design engineers will then assist during the design process to rectify these regions.

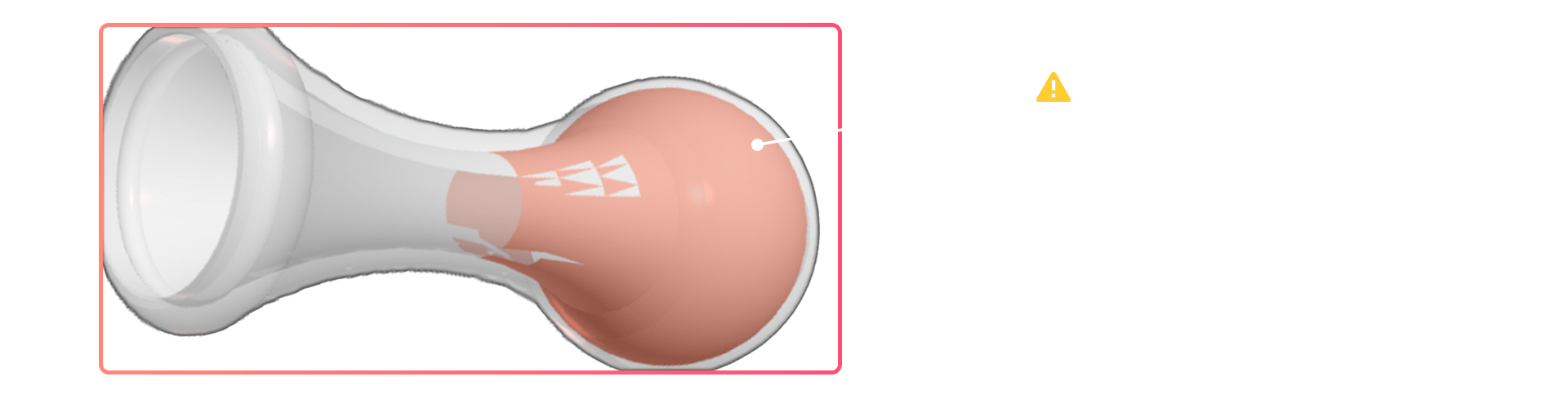

Internal Volume Detection

Internal regions of a part can be very difficult to machine and increase the cost of a part significantly. Our software detects and highlights these areas, which can then be reviewed by our engineering team.

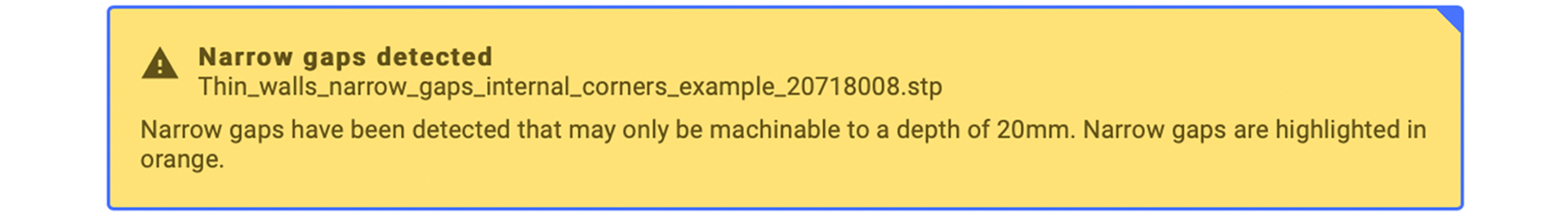

Narrow Gaps Detection

Narrow gaps in a part can sometimes not be manufactured to the desired depth.

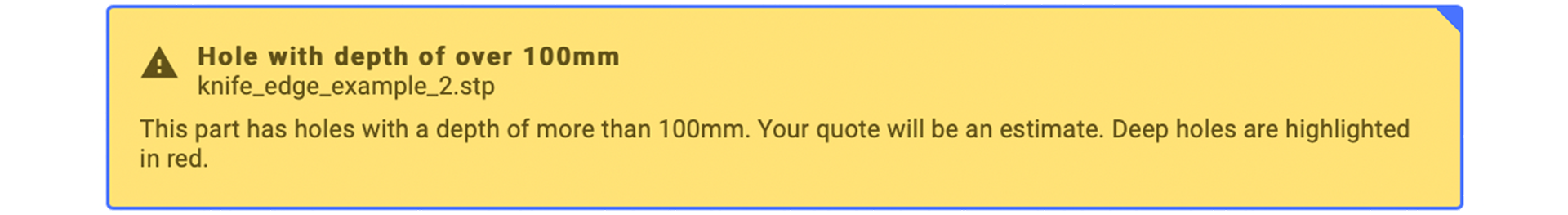

Deep Holes Detection

Deep holes in a part can be difficult and expensive to machine out. Our software detects and highlights these areas, which can then be reviewed by our engineering team.

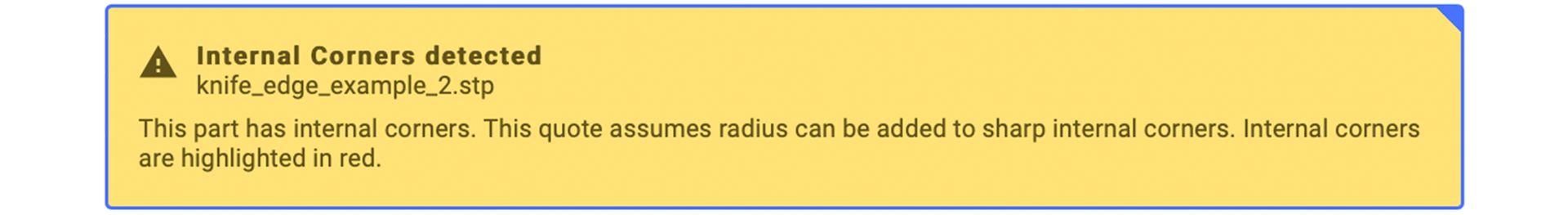

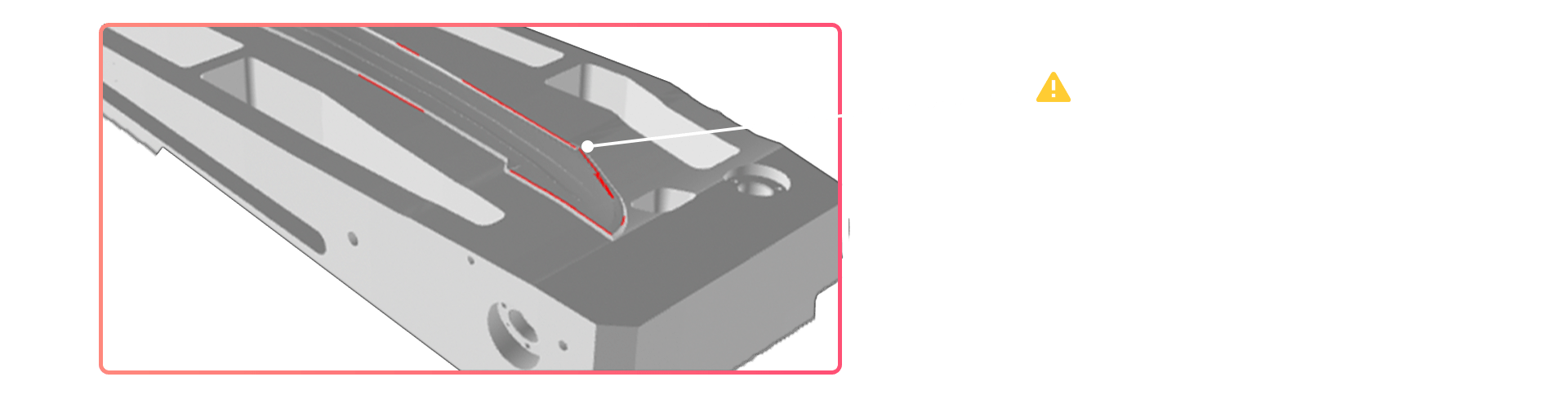

Internal Corner Detection

Internal corners are edges in a part that cannot be machined easily, due to the geometry of the tooling head.

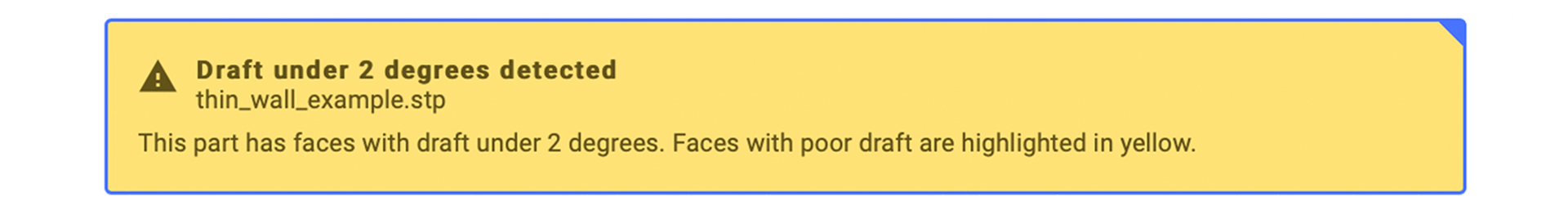

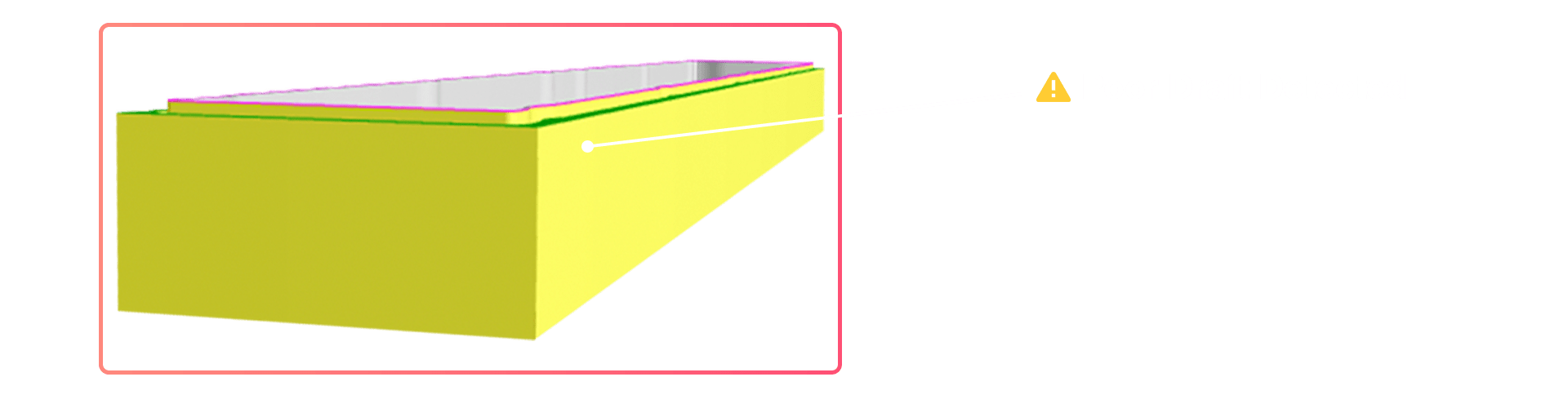

Detection of Poor Draft for Components

Automatic mold solutions are generated for components uploaded to the site. The draft value of each face in the mold solutions is calculated, and faces with a draft of less than 2 degrees are highlighted, as these will make the component difficult to remove from the mold.

See our blog post on this: Tooling Essentials - Draft Angles

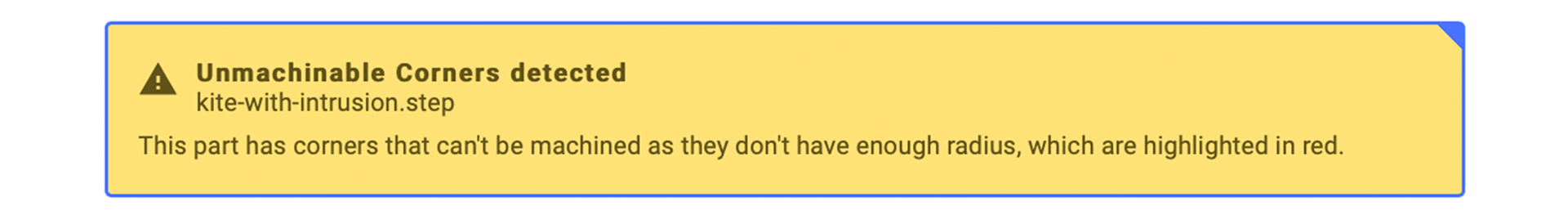

Unmachinable Points (no radius)

Points in a part where the faces meet at too small an angle, so are unmachinable. A point in a deep triangular feature of a part should trigger this.

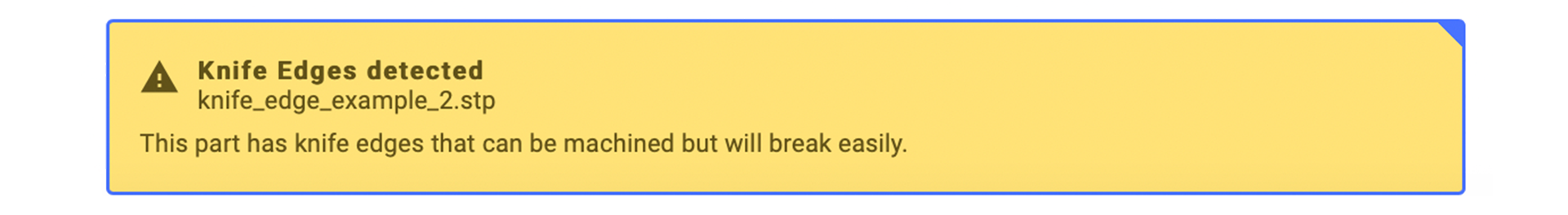

Knife Edges

Edges in a part that join two faces at a tight (under 20 degrees) angle. Sharp edges that are likely to break.

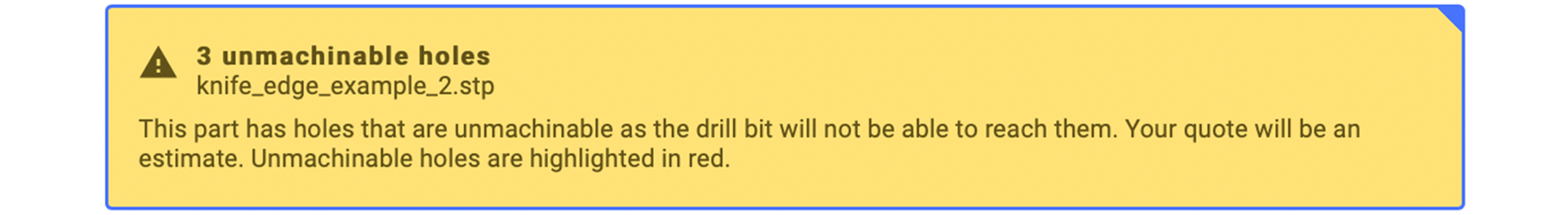

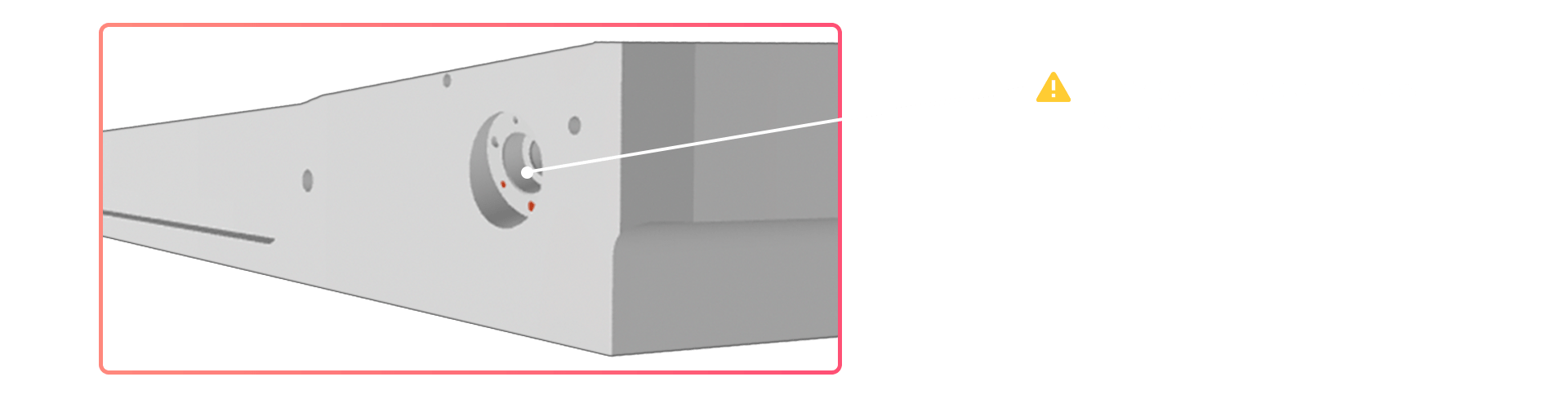

Unmachinable Holes

Holes that are blocked by some other part of the mesh so that a machining tool would be able to get into them. For example, a hole in a deep but narrow cutout section of the part. Our software detects and highlights these areas, which can then be reviewed by our engineering team.