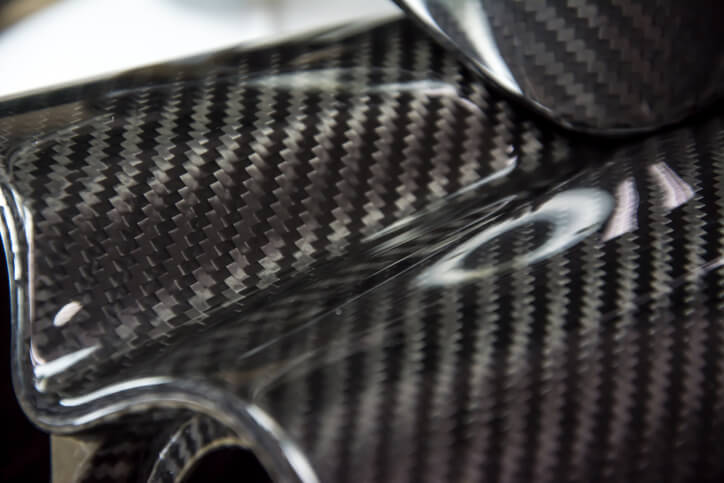

The majority of our clients are in the aerospace sector and we have extensive experience with all kinds of parts both exterior (wing panel & spar molds) and interior (panel and aircraft seat molds).

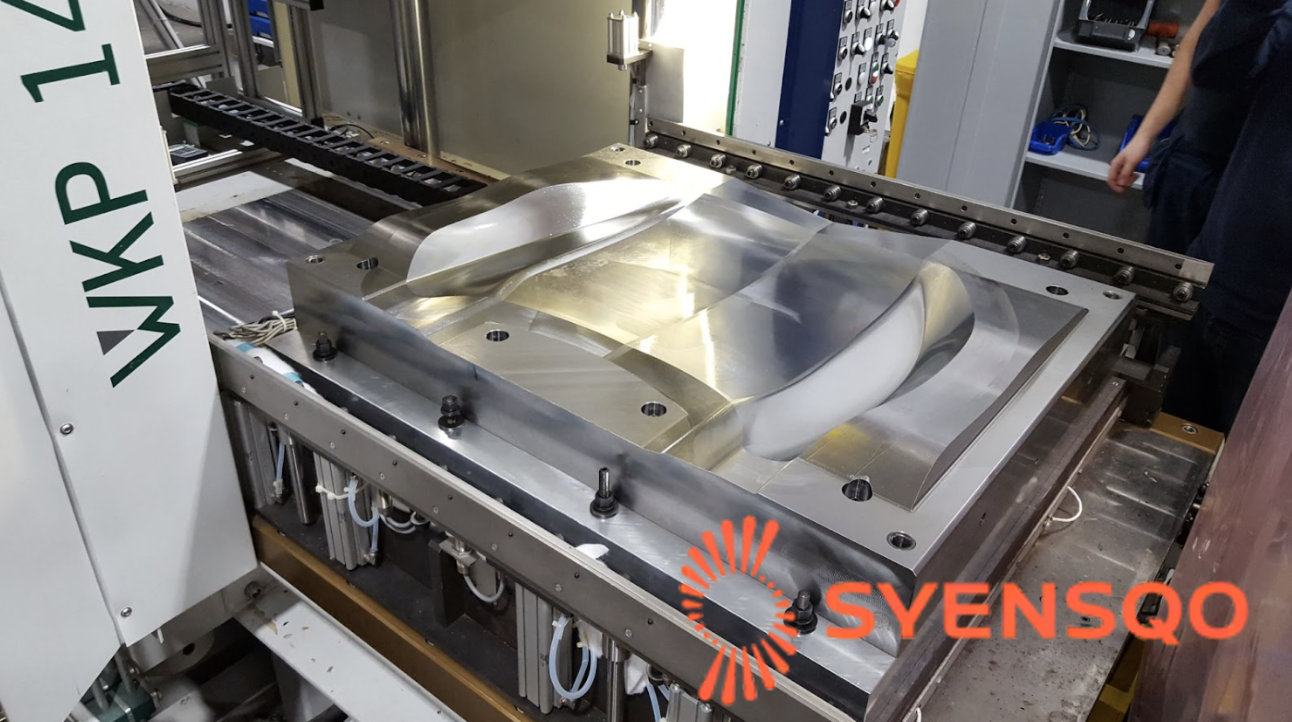

Mold Manufacturing for Aerospace

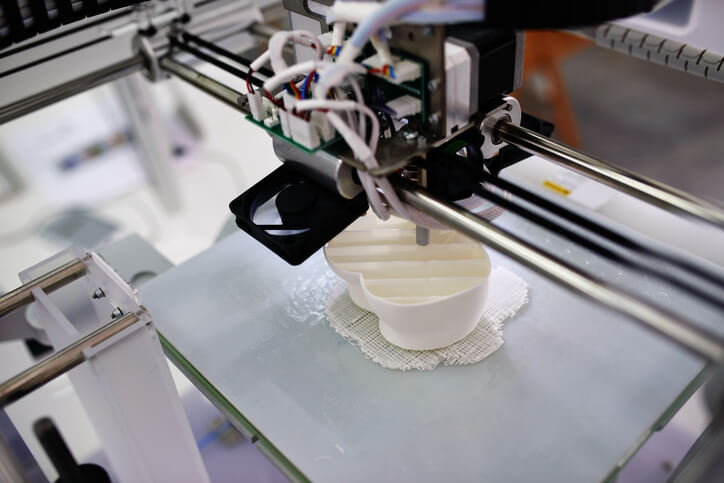

Precision and quality is essential to get tooling done right first time. Plyable matches the right manufacturing partners for your tools without compromise on lead time or quality.

Our clients choose us for our wide range of capabilities and our experience in mold design.

Plyable’s ability, experience and capabilities have attracted the attention of some of the worlds largest aerospace companies.