We’ve just secured our 1st EU and UK patent for our Automated Molding feature!

Plyable has just secured its first UK and EU patented technology for our Automated Molding technology feature, accessed through our Plyable manufacturing portal.

This new level of protection will help drive innovation for our clients in the Aerospace, Automotive and Marine sector and support with research and development.

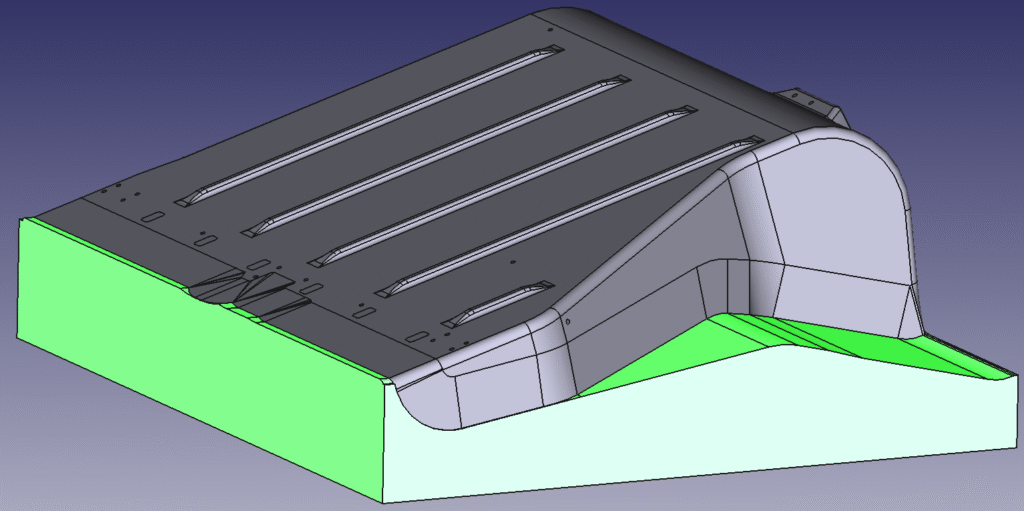

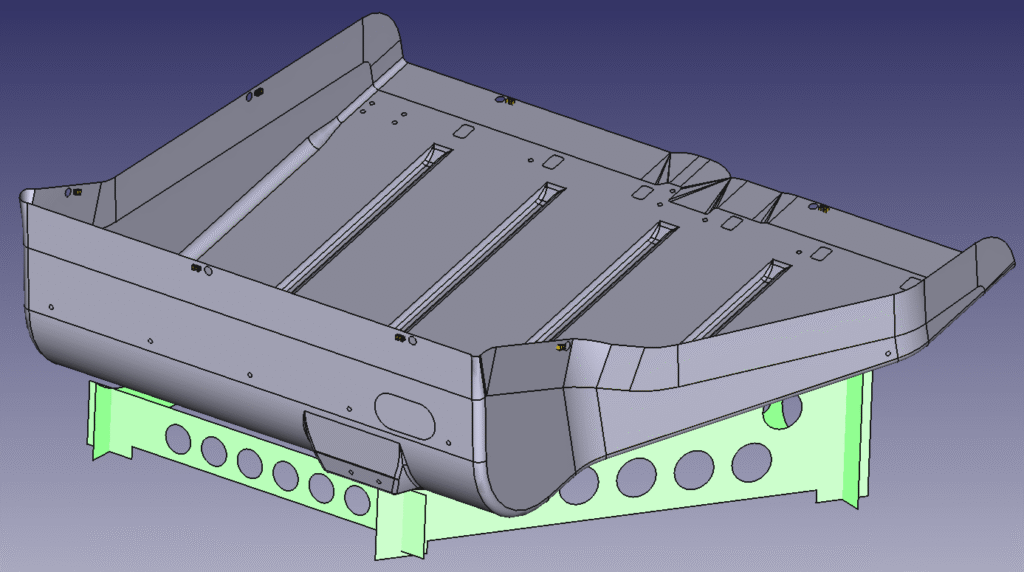

Automated Molding technology allows our clients (our software users) to upload component/part design STEP files into our machine-learning system. Plyable’s system computes pull directions, automatically extrudes a shape’s boundary and adds elements such as laser targeting holes, to generate a precise STEP file of the mold. The process is 100% computer-driven, producing supplier-ready files in a matter of minutes.

Rather than spending enormous amounts of time in trial and error and sourcing manufacturing costs use our mathematical and science-based manufacturing solution to auto-generate ready to use mold design files.

What is a technology patent?

A patent is the legal right granted by the government to protect new inventions in technological solutions. The inventor’s given exclusive rights to make, use, sell or license the invention for a capped period (normally around 20 years).

The idea behind a patent is to protect the rights of the invention creator who are required to disclose how the invention works in detail so that others can comprehend its usage. Patents are granted to solutions that deliver and are one of a kind and will be useful in the industry they are intended for. Having a patent in place ensures that no other business can copy our human intelligence and therefor our intellectual property meaning we can remain at the forefront of this offering.

What are the real benefits to using our Automated Molding feature?

Our invention creates even more technological support to aid our time-constrained clients. This feature helps with:

Timesaving > Upload your existing part/component design to receive an instant model. Our mathematical and science-based capabilities enable us to create a truly bespoke and speedy solution to address getting parts into production effectively.

Accuracy > We employ mathematicians, computer scientists, and user experience experts to interact constructively with our design engineering team. The combined experience allows us to build, develop, test and release tools once we are confident, they’ll deliver. As we say, we design right, first time, every time.

Reduced risk > The majority of our projects are managed through our automated digital manufacturing journey without much human intervention. For more complex projects we have our skilled composite engineering team on hand to assist with every stage of manufacture; from design to engineering, and from production to logistics. Our strong background and expertise in the composite and metallic sector mean you will receive complimentary direct consultancy if required when designing your automated mold.

Access to our global supply chain > When you sign up with Plyable you will have access to over 100 manufacturers giving your business more experienced expertise in a niche sector, widening your team’s capabilities, insight into best practice manufacturing and further opportunities to scale your own business offering.

Building our brand > We have only been in existence around 8 years, and only in the last 4 years have we been rolling out our software. We want to show we are credible, thought leaders. We are here to improve the market for existing engineers, who each have their own focus and want to see faster progress in sustainability, materials, methods and agility during their careers whilst inspiring graduates and students to collaborate with us to get the most of their progressive minds.

Working to high standards with IS9001

We grade and vet every supplier before adding them into our software’s network. They must meet IS09001 standards and there are certain Plyable directed competencies they will need to prove before given access to our client briefs. We continuously manage our partners to keep a close eye on product quality standards, new machinery and methodologies and customer service output.

We also collaborate with like-minded clients, and we feel gaining patents helps protect their trust, faith, and direction to our mission; to providing a seamless, turnkey composite and metallic manufacturing journey using our custom AI manufacturing software.

What this patent means to Plyable

For Plyable, leading the way in AI technology software solutions is important for several reasons. We want to develop, implement better features, and expand our features as our knowledge and technology itself advances. To enable us to do this we require investment from technology funders so by demonstrating we are technically minded, innovative and ambition our patent builds trust and confidence in our team’s ability to deliver.

Our new patent is like a shield to protect our progressive machine-learning developments. We will continue to invest in patents to strengthen of market position and increase the unique value of our software business.

Written by Kristy McMillan on 01.09.2025. For more information on this topic please contact info@plyable.com.

Stay connected.

Follow us on LinkedIn or sign up to our marketing newsletter.

- See our latest projects first

- Connect with our expert team

- Access deals and promotions

”Great communication, the website was very good and allowed easy sharing of files & communication.

The team were a great help and ultimately designed us a fantastic tool”

-Automotive client, July 2025

Wish to speak to us about a project?

Fill out our contact us form, we will always aim to get back to you on the same working day

Book in directly with Sales

info@plyable.com | 01865 686164

Joshua England – Global Sales support