The universe is the new limit.

Our aerospace composite clients trust us to know how to solve complex manufacturing challenges in a fast, agile and leading-edge way. Our job is to help manufacturers stay ahead of the curve by providing aerospace mould tooling at record speed.

As the only global software manufacturer overseeing the end to end production of high quality composite molds and parts, Plyable is the tech-leader in tech-driven manufacturing. Our ability, experience and approved supply chain have attracted the attention of some of the world’s largest aerospace companies within space, commercial, private and defence.

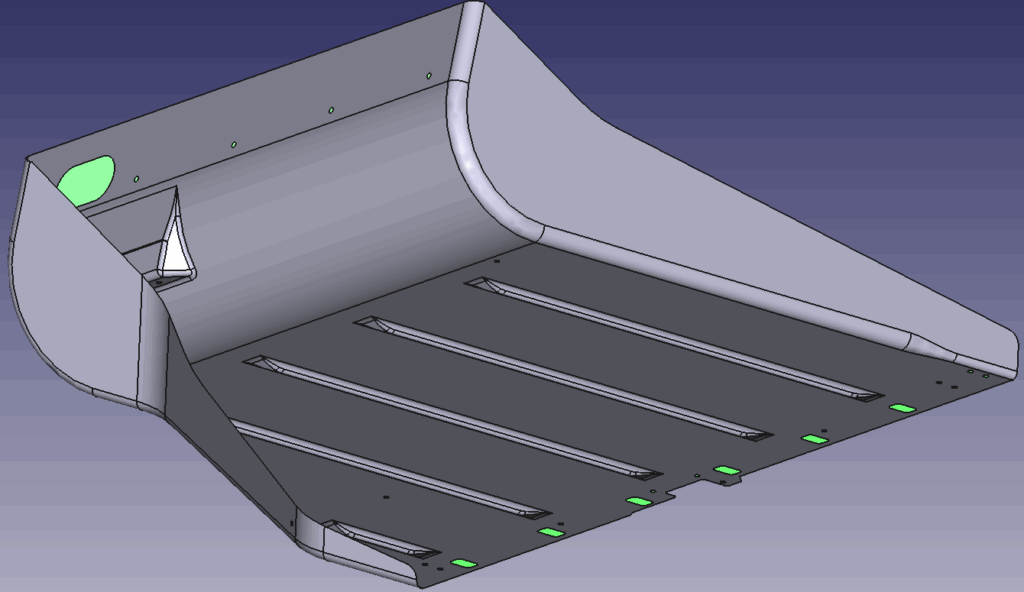

With a focus on finding lightweight composite solutions we have designed and manufactured thousands of tooling and parts through our machine-learning software. Projects have included designing wing spars up to 14m, creating bespoke fuselages for drones, product development for eVTOL enterprise projects and facilitating with manufacturing such as internal trims, control panels, battery box casings and door components across aircraft and space.

Great communication, the website was very good and allowed easy sharing of files & communication. The team were a great help & ultimately designed us a fantastic tool”

– Aerospace client, August 2025

Manufacturing, Remastered.

Plyable’s leading software helps your business go further. Our distinguishable machine-learning platform connects you to the world’s best composite aircraft manufacturers.

Experience your entire production process through our end-to-end manufacturing solution:

Find out more

- Produce parts and tools in unison or separately, including low to high volumes in as little as 3 days

- Auto-generate molds through our machine-learning software. Simply upload your part design, our software will do the rest

- Onboard us for direct access to hundreds of approved and vetted suppliers, all working to the same IS09001 standards

- Consult with composite market experts in Engineers, Software Developers and gain access to leading manufacturing methods

Ultralight aircrafts with outstanding speeds.

Aircraft such as the Boeing AH-64 Apache, one of the US-designed most advanced attack helicopters, known for its network-centric capabilities and combat qualities, uses around 1500 composite components to ensure it stays as lightweight as possible. Originally, the aircraft had thousands more metal components, so a move towards composite parts such as updating the material of the helicopters main rotor blades has significantly improved the craft’s speed and durability.

Design right, first time, every time.

Excel with AI software

Experience faster, leaner production through our custom built software

Access suppliers

Access hundreds of approved suppliers, each offering unique capabilities

Offload capacity

Quickly find production support to meet your deadlines when your team is over-stretched

Expert support

Our Plyable Engineers have significant D2M experience across our sectors

Composite Community

Be part of a group sharing best practice manufacturing methods and insights

Aerospace manufacturing sectors

Commercial Aircraft

Defence – Military Aircraft

Defence – Miliary Equipment

Space/Satellites

General Aviation

Drones (UAV)

Aerospace Engineering Capabilities

Our aerospace composites manufacturers have a breadth of expertise across the following services:

Services

- Inspection Reports

- Sealing

- Polishing

- Powder Coating

- Painting

- CAD Design

- Non-Destructive Testing (NDT)

- Project Management

Materials

- Carbon Fiber Reinforced Plastic (CFRP)

- Glass Reinforced Plastic (GRP)

- Aluminium

- Steel

- Expoxy/PU Tooling Board

- ROHACELL Foams

Methods

- Pre Preg

- Infusion

- Compression Moulding

- Resin Transfer Moulding

- Wet Lay Up

- Filament Winding

- CNC Machining

- Additive Manufacturing

- Modular Layup Tooling for aerospace

Read our latest aerospace blog

We’re not just excited about what’s happening on the show floor at JEC 2025 – we’re eager to see how the industry is evolving…

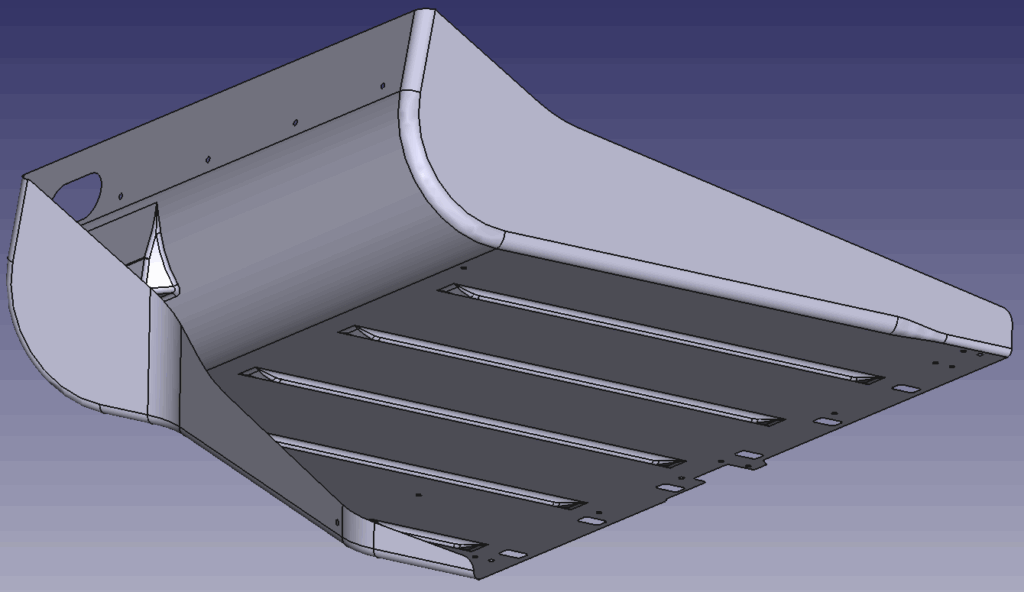

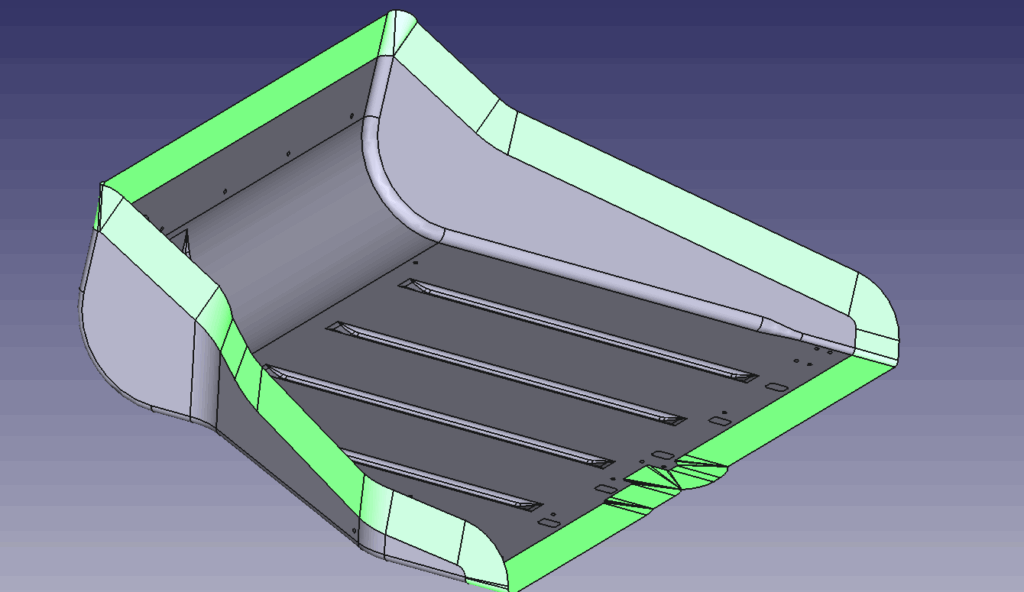

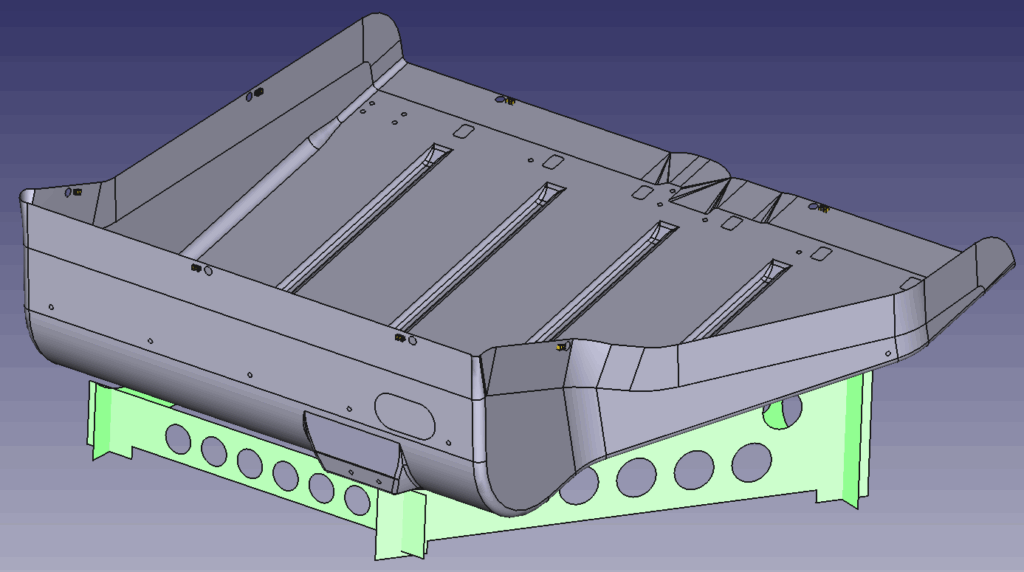

Introducing our patented ‘Generative Molding’ feature

Generate instant tooling designs ❯❯❯❯❯

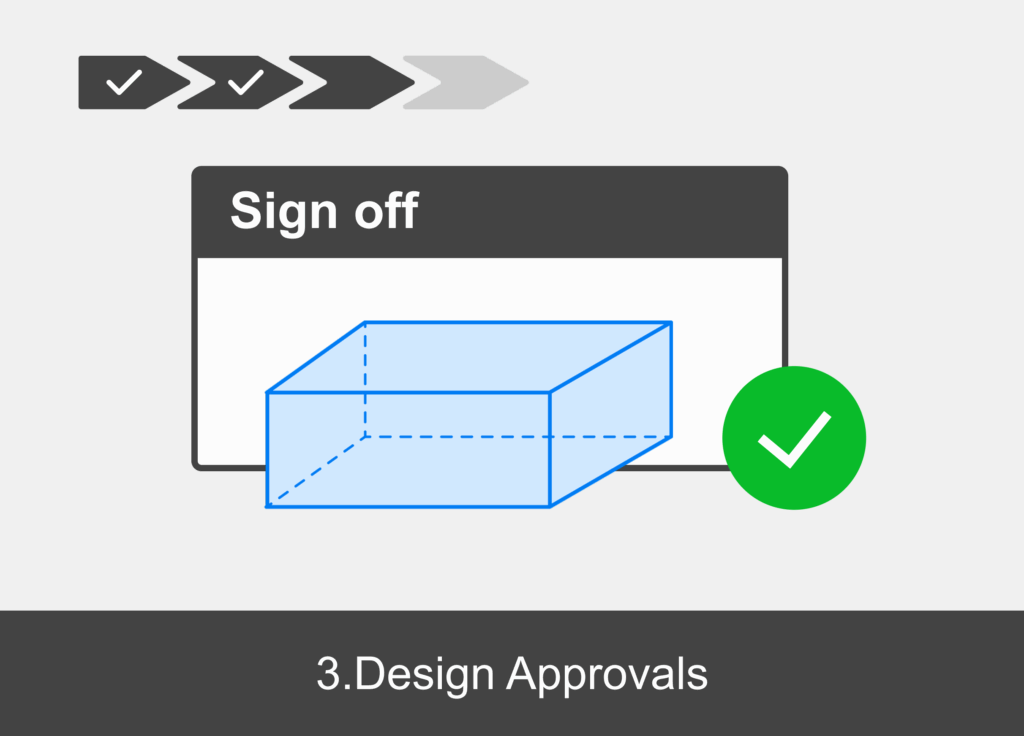

Experience our unique patented technology Create instant precision tooling from a component STEP file.

Plyable’s specialist engineers, mathematicians and computer scientists have designed this leading-edge feature enabling you to receive fast quality tooling complete with full technical instructions and a pattern.

Phase 1

Calculate molded surface

Phase 2

Fill cutouts and holes and create runoff

Phase 3

Extrude boundary to mold box and fill faces

Phase 4

Add backing structure & LT holes

Discover our AI-driven manufacturing software.

Speed up your composite and metallic mold and part manufacturing, without compromising on quality.

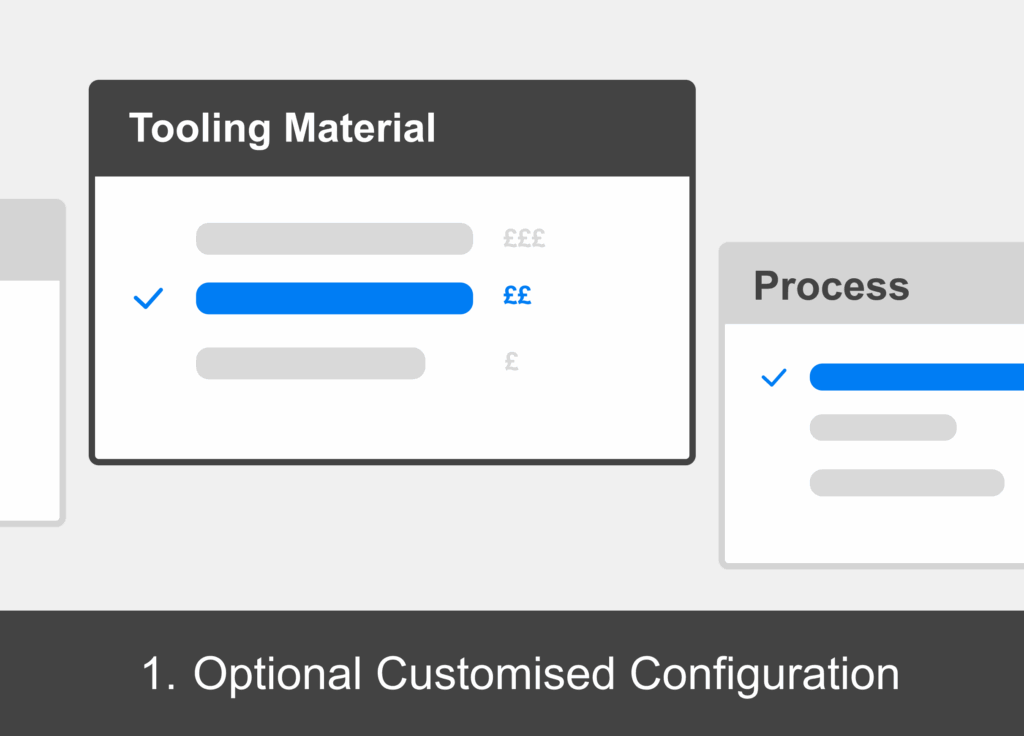

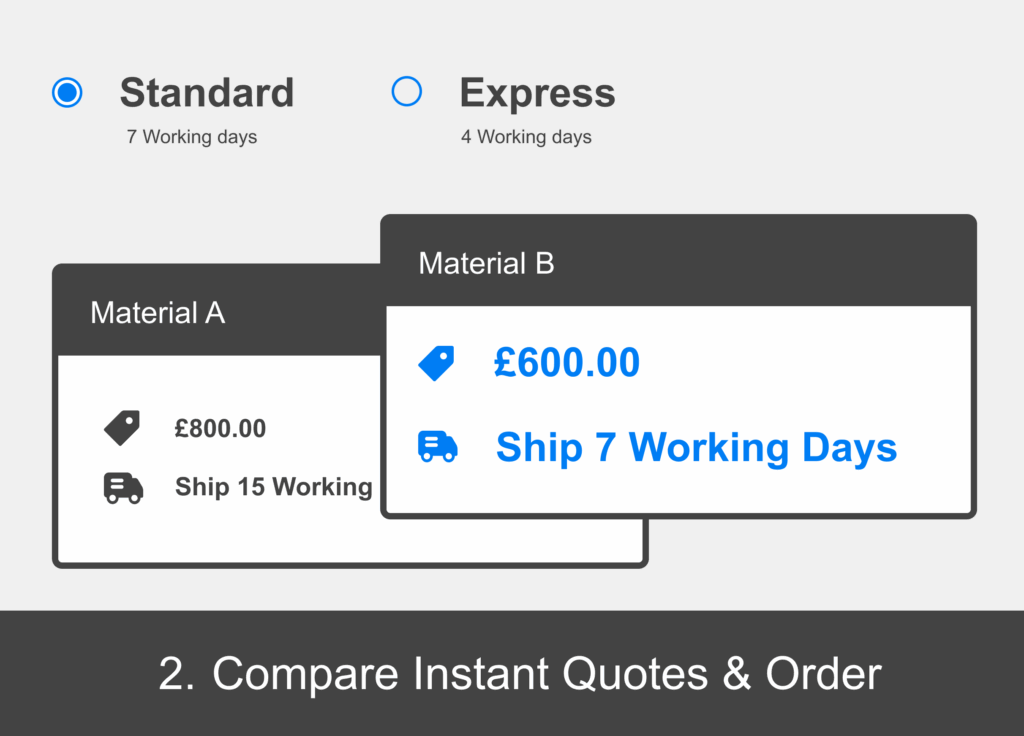

Simply upload your CAD file via our Plyable Portal to receive an instant quote:

Bank Grade Security

Wordwide Delivery

Wish to speak to us about a project?

Fill out our contact us form, we will always aim to get back to you on the same working day

Book in directly with Sales

info@plyable.com | 01865 686164

Joshua England – Global Sales support

Stay connected.

Follow us on LinkedIn or sign up to our marketing newsletter.

- See our latest projects first

- Connect with our expert team

- Access deals and promotions

”Great communication, the website was very good and allowed easy sharing of files & communication.

The team were a great help and ultimately designed us a fantastic tool”

-Automotive client, July 2025

FAQs

How can I upload my files?

Select from the ‘Create a Mold, Create a Part and Trial our software’ buttons above. From there you will be taken to our Plyable software interface where you can upload your design file. The website will guide you through the full manufacturing process. Simply follow the steps and you’ll receive progress updates via email. Your account will enable you to track the progress of your project in real-time. You’ll also be able to upload documents and chat live with our Engineers who will be guiding the process.

What are your payment terms?

Our standard payment term is 30 days. Upon receipt of purchase order and a 30% deposit payment we will commence design or manufacturing process. The outstanding cost is due upon completion. For large projects or more complex work we can be flexible around payment terms and we can bill in phases to help you manage your project costs.

I’d like to get in touch about a project, what’s the best way?

If you know what manufacturing requirements you require you can upload your file here, answer a few short questions and receive an instant quotation. If you would like to talk to our Sales, Customer Service or Engineering team first then you can either fill out a contact us form as above (see pink contact us box), email us at info@plyable.com or call 01865 686164