Manufacturing composites for defense and military equipment

Lighter. Stronger. Smarter.

Manufacturing composites for defense and military equipment is one of our key focuses. The demand in this sector across human aid, surveillance, operation and combat has been driven by aging systems that need replacing, newer technology systems that require flight infrastructure just as powerful as well as rising global conflict. With a mission to offer a digital manufacturing revolution to the composite world through our seamless, customisable turnkey solution driven by leading engineers, backed by technology and partnership. At Plyable you’ll find 360 degree support for your D2M defense products. Find out more about who we are and what we do on our About us page.

Crafting composites that take command.

The likes of Carbon Fiber, Glass Fiber, and Kevlar reinforced polymers have become the cornerstone choice of material for many modern military aircraft. Their lightweight high-strength, stealthy airframes and durable qualities allows for a reliable and high-powered performance in military operations.

Our team at Plyable for a number of years has worked with military and defense teams across the world to level up their manufacturing output. Our tech-led consultancy has found faster ways to bring products to market, trial new processes and methods of part and tooling creation, sourced bespoke materials for niche projects whilst delivering intelligent forward-thinking solutions to major military challenges.

Our experienced design, engineering, commercial, manufacturing and logistics consultants will work closely with your design team. At Plyable we are different because we’ve developed the world’s first end-to-end manufacturing portal which streamlines the D2M project management process whilst reducing risk, providing instant quotes and giving clients open access to an approved global supply chain.

Design right, first time, every time.

Excel with AI software

Experience faster, leaner production through our custom built software

Access suppliers

Access hundreds of approved suppliers, each offering unique capabilities

Offload capacity

Quickly find production support to meet your deadlines when your team is over-stretched

Expert support

Our Plyable Engineers have significant D2M experience across our sectors

Composite Community

Be part of a group sharing best practice manufacturing methods and insights

Designing drones that provide

Weight reduction

Lightweight materials contribute towards increased fuel efficiency, payload capacity and range. Composite-made aircraft provide a sharper rate of climb and improved acceleration as well as the ability to take off and land on shorter runways.

Strength & durability

High-stress environments of military operations necessitate exceptional structural strength. It’s important that lightweight aircraft can manoeuvre under high-g force whilst having airframes that can withstand structural integrity even after taking battle damage, which is why many composite materials are fit for purpose.

Design Flexibility

Flexibility in defense aviation is achieved primarily through Modular Open Systems Approach (MOSA) which include multi-role capability and future proofing. Designs should support the production of multiple types of aircraft, be suitable for today’s technology systems and be easy to repair for longevity.

Industry challenges

Here’s some of the key challenges we’ve identified through our established relationships with military engineers:

Time from design to theatre of operations.

Scaling production

Cost of materials & production

Variability in production

Supply chain resilience

Data security and export control.

Development timescales are moving from decades to months for new defence platforms. The composite industries supply chain and development process need to adapt to ensure airframes and composite structures can be delivered on demand to tight lead times. Plyable’s integrated software portal can transform CAD file to delivered product in as little as a few days – scale and complexity depending.

The trend in the defence market is moving towards smaller developers that are more able to meet able to agility requirements in order to scale faster. Composite niche experts are more likely able to meet complex tooling and process technology faster than larger consultancies whilst also having the connections to scale at the rates required.

That’s why our Plyable portal is underpinned with approved, experienced partners that are leaders in their specific composite manufacturing fields.

The cost of materials and production in defense aircraft is higher than for commercial airplanes. Costs are less associated to the weight and are assigned more to the extensive engineering hours, specialised labour methods, the unique processing of exotic materials, and the need to recoup decades of R&D over a limited production run.

Having a standardised production processes is key to scaling quickly and ensuring performance across all designs produced at high rate to minimise risk of failure in the manufacturing process. Our technology has been created to streamline and provide clarity to all stakeholders within the production process to make sure we leverage the traditional routes we know that work, whilst at the same time harnessing technology to enhance the process.

With geopolitical tensions rising globally, resilience needs to be built in to the supply chain with multiple options for supply from different countries. Plyable has sourced key manufacturing partners in regions where there is high demand for defense aircraft. All suppliers are approved by our in house partnership team so you can be sure quality standards will always be met.

Data needs to be handled carefully and controls need to be in place to protect it. We understand defense and military’s operations need optimal protections so we’ve ensured our solution is of bank grade security.

Our tech-led approach to manufacturing helps businesses:

Strengthen through capability

Our technology opens doors to find innovative methodologies and materials in our supply chain chain. When new developments arrive in the composite industry we ensure your team is in first place for production opportunities.

Scale through our global supply-chain

Our vetted and approved supply chain work to a minimum ISO 9001 standard. We work closely with our suppliers to ensure price, product quality and customer service matches our own brand and future ambitions.

Stay ahead using our connections

Understanding the unique challenges around innovation, R&D and sustainablility then using technology to find new ways to improve these areas of composite manufacturing is at the heart of our offering.

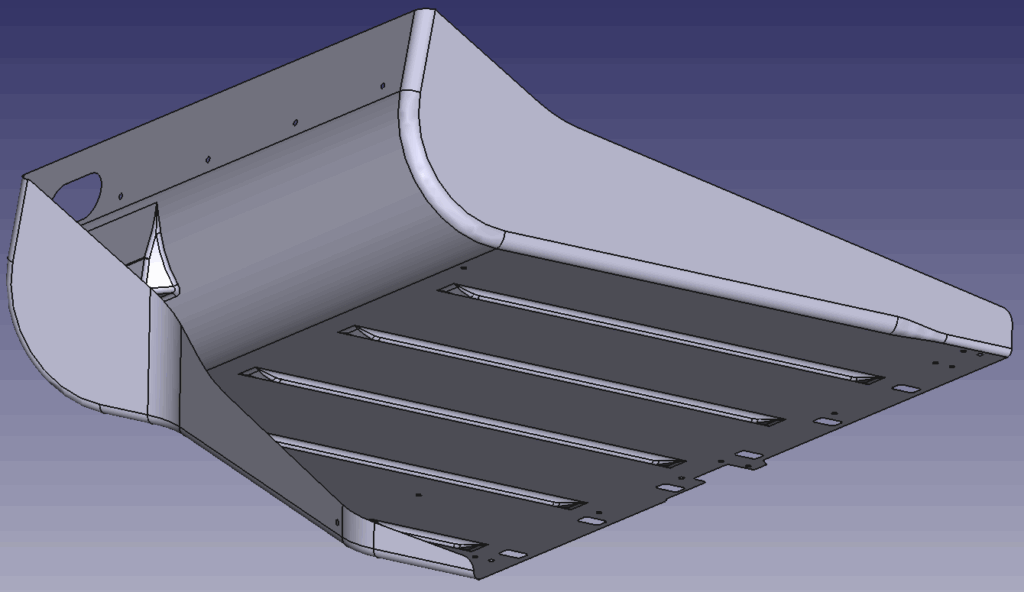

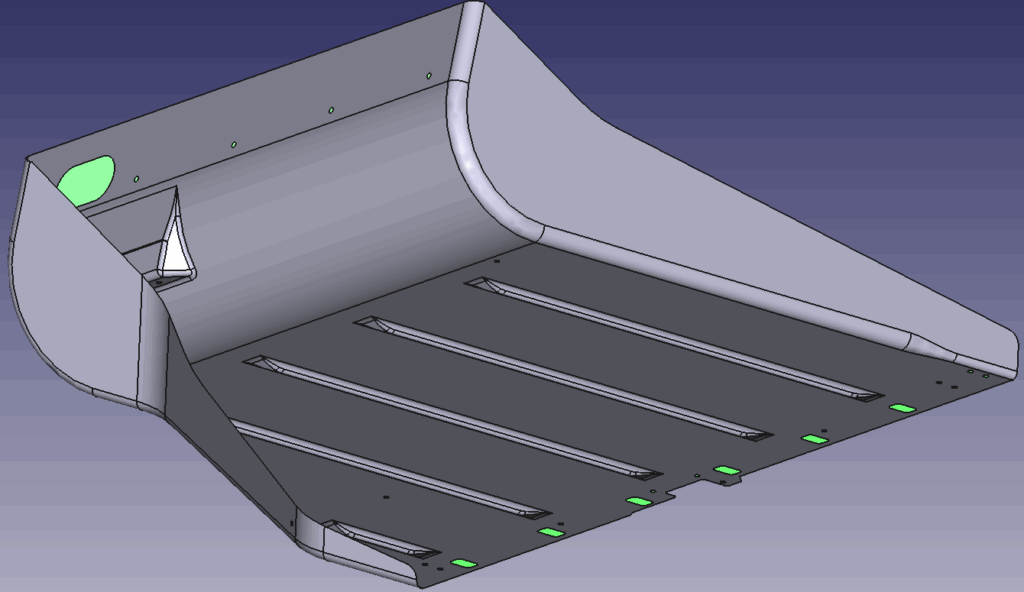

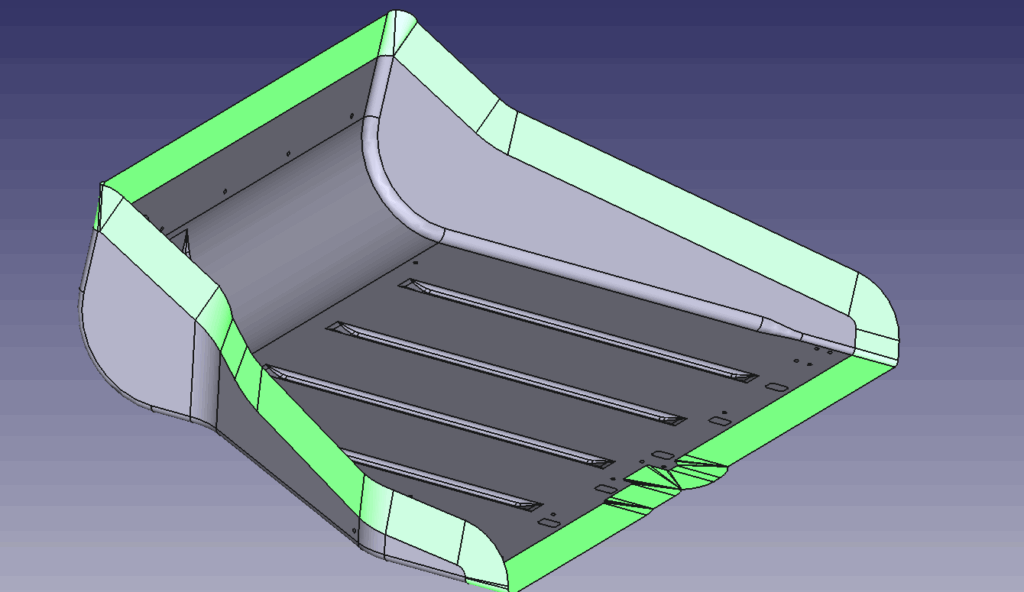

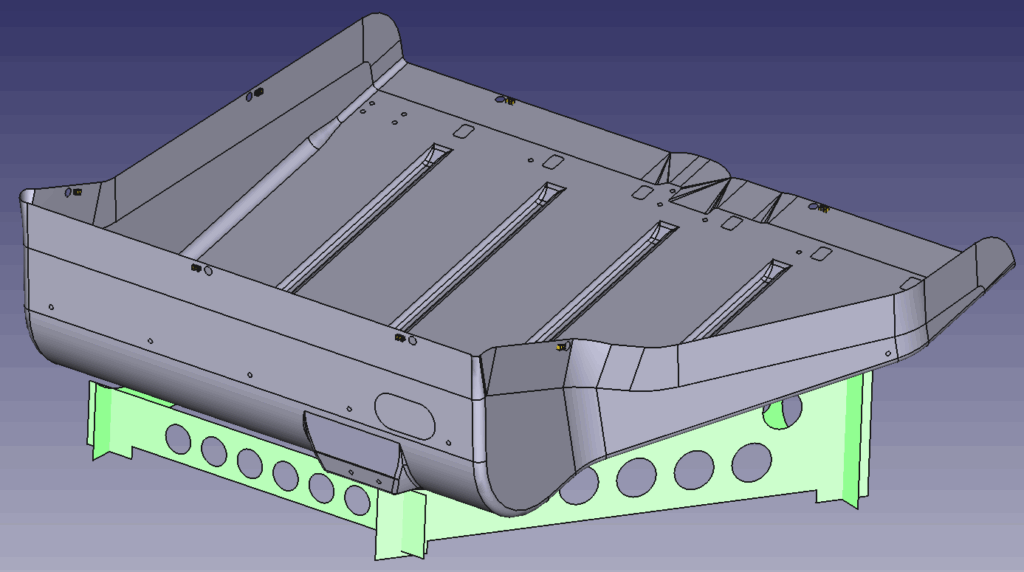

Introducing our patented ‘Generative Molding’ feature

Generate instant tooling designs ❯❯❯❯❯

Experience our unique patented technology Create instant precision tooling from a component STEP file.

Plyable’s specialist engineers, mathematicians and computer scientists have designed this leading-edge feature enabling you to receive fast quality tooling complete with full technical instructions and a pattern.

Phase 1

Calculate molded surface

Phase 2

Fill cutouts and holes and create runoff

Phase 3

Extrude boundary to mold box and fill faces

Phase 4

Add backing structure & LT holes

Plyable Insights

Our team attended Advanced Engineering Show; the UK’s leading annual event for the engineering and manufacturing sectors, held at the NEC, Birmingham.

Advanced Engineering is one of our favourite’s as it demonstrates the entire industrial ecosystem connected to high-value manufacturing and supply chain solutions.

Get in touch for a free consultation

Complete our contact us form for a rapid response:

Please note that buy completing this form you agree to be contacted by our sales team and your email will be automatically added to our marketing communications list which you can opt out of at any time.

Or book a call in with our sales support team today:

For a completely free discussion, to gain a better understanding how we can help your teams specific needs or to talk through your quote, speak to our dedicated and supportive team.

Discover our AI-driven manufacturing software.

Speed up your composite and metallic mold and part manufacturing, without compromising on quality.

Simply upload your CAD file via our Plyable Portal to receive an instant quote:

Bank Grade Security

Wordwide Delivery

Stay connected.

Follow us on LinkedIn or sign up to our marketing newsletter.

- See our latest projects first

- Connect with our expert team

- Access deals and promotions

”Great communication, the website was very good and allowed easy sharing of files & communication.

The team were a great help and ultimately designed us a fantastic tool”

-Automotive client, July 2025