28 April 2018 | guide

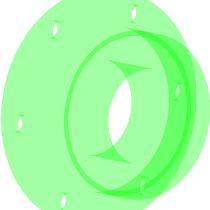

Composite parts are made by layering composite material onto one or more molds. Getting the mold design and manufacture right is crucial to a good end result. With Plyable all you need to do is upload a part design and with a click you will receive a mold ready for lay-up of composite material.

-

Design the part

Create the part in a CAD tool and upload the .STEP file to Plyable.

-

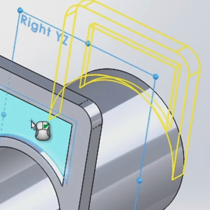

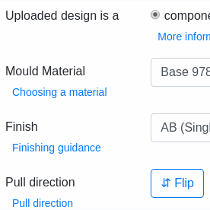

Online mold design

Plyable technology simulates the design and manufacturing process in real-time

-

Instant online quote

Plyable will provide you with the cost and lead time to manufacture the mold

-

Manufacture

Plyable manufacture the mold using CNC or 3D printing processes

-

Finishing

The mold is sealed and releasing agent is applied by Plyable

-

Delivery

Track the order as it is processed and delivered

-

Material lay-up

You receive the mold ready to lay up composite material