Get ready, set, GO! with Plyable

With a mission to offer a digital manufacturing revolution to the composite world through our seamless, customisable turnkey solution driven by leading engineers, backed by technology and partnership, you’ll find 360 degree support when you use Plyable for your D2M motorsport products.

You can find our more about who we are and what we do on our About us page.

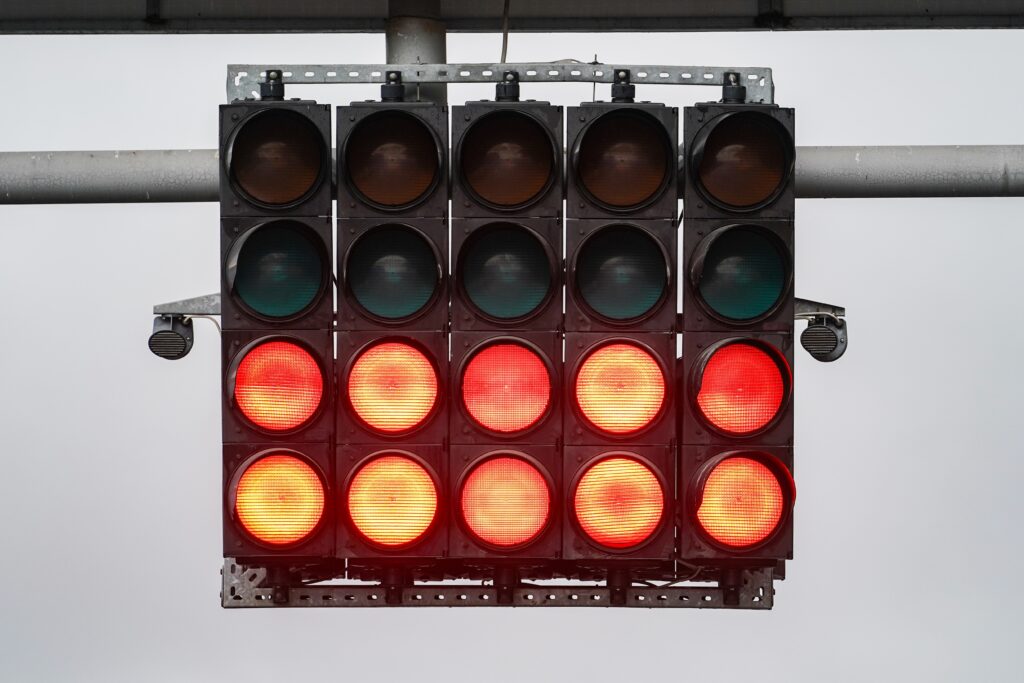

Crafting Champions: The Art of Motorsport Manufacturing

In the fast-paced world of motorsport, every gram and millisecond counts. Our composite machine-driven manufacturing solution combines cutting-edge materials, machinery, technology and craftsmanship to deliver components that push the limits of performance.

From lightweight carbon fibre bodywork to structural chassis elements we pride ourselves on producing high-strength, low-weight solutions that meet the rigorous demands of competition. Whether our F1 or Nascar teams are looking for methods like CNC machining, wet lay up or filament winding, struggling with over-capacity or needing pioneering input from our highly qualified Design Engineering team our goal is to provide you with the products you need to get you into first place position.

We always strive to ensure every part delivers unmatched strength, aerodynamic efficiency, and reliability to help teams gain the crucial edge where it matters most – on the track.

Design right, first time, every time.

Excel with AI software

Experience faster, leaner production through our custom built software

Access suppliers

Access hundreds of approved suppliers, each offering unique capabilities

Offload capacity

Quickly find production support to meet your deadlines when your team is over-stretched

Expert support

Our Plyable Engineers have significant D2M experience across our sectors

Composite Community

Be part of a group sharing best practice manufacturing methods and insights

Additive 3D manufacturing

Bio-materials for the win

Motorsports partnerships

Additive manufacturing is the process of creating 3D objects from design files by adding material layer by layer to create a specified design. We have seen a huge trend in motorsport teams choosing this technique to add a lightweight, robust and intricate solutions for components and molds to produce racing cars.

Bio-materials such as flax, hemp and kenaf are becoming more popular substitutes for glass and carbon fibre due to their ability to meet sustainability criteria’s, as well as in some cases exceed in lightweight performance. We work with a number of manufacturers who specialise in alternative solutions to stay competitive, particularly in F1 motorsport.

Plyable offer long term partnership models with motorsports teams to provide design, tooling and manufacturing services at lower costs, shorter lead times and using the state of the art of composite tooling technology.

Want to know more? Send us an email to info@plyable.com

Industry challenges

Here’s some of the key challenges we’ve identified through our established relationships with motorsport engineers:

Balancing weight and strength

Simulation and Analysis

Rapid Development Cycles

Sustainability & waste reduction

Complex geometries

Achieving maximum stiffness-to-weight ratio whilst meeting crash safety and structural integrity requirements is a constant trade-off. As newer technologies evolve to support these challenges, manufacturers and material suppliers are pushing the boundaries to provide newer methods, such as 3D printing. Our portal can connect you to the right types of suppliers to help achieve your teams ambitions.

Finite Element Analysis (FEA) for composites is complex due to anisotropic material behaviour and layup variability. Plyable’s tech team can provide manufacturing variability; a clear digital thread between design, FEA, and production as well as fast accurate traceability so you can keep be clear with iterations and strategic with your improvements.

Motorsport teams need quick turnaround from concept to track-ready parts. We understand this puts a huge about of pressure on simulation and manufacturing accuracy. That’s why we’ve developed our D2M solution to mitigate risk and reduce the chance on end production re-production.

Carbon fibre offcuts and single-use prepregs generate significant waste and whilst recycling and reuse technologies are still maturing motorsport teams may need to consider other routes to reduce their emissions. Our Plyable portal can connect you to a wealth of suppliers who offer credible alternative solutions to help you sustain speed whilst reducing waste.

Aerodynamic bodywork and structural components often have complex shapes that are difficult to laminate or mold without wrinkles, voids, or delamination. Our experienced design engineering team have spent many years re-designing speed focused solutions for complex fascia’s and intricate parts across many industries can help you find award-winning methods. Our automated mold feature can also generate fast tooling solutions to meet the need for quick turnaround parts.

Our tech-led approach to manufacturing helps businesses:

Strengthen through capability

Our technology opens doors to find innovative methodologies and materials in our supply chain chain. When new developments arrive in the composite industry we ensure your team is in first place for production opportunities.

Scale through our global supply-chain

Our vetted and approved supply chain work to a minimum ISO 9001 standard. We work closely with our suppliers to ensure price, product quality and customer service matches our own brand and future ambitions.

Stay ahead using our connections

Understanding the unique challenges around innovation, R&D and sustainablility then using technology to find new ways to improve these areas of composite manufacturing is at the heart of our offering.

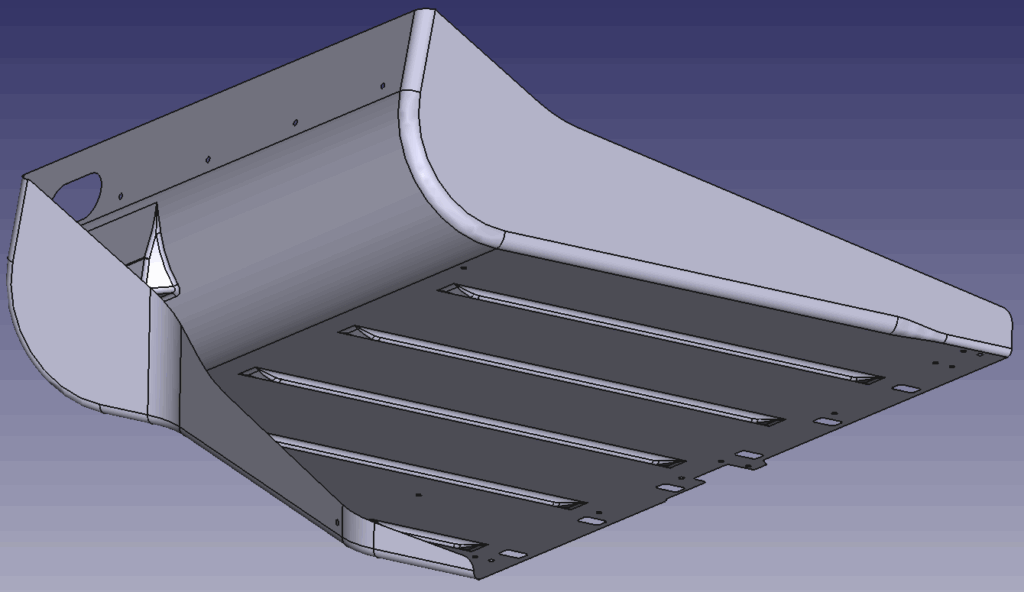

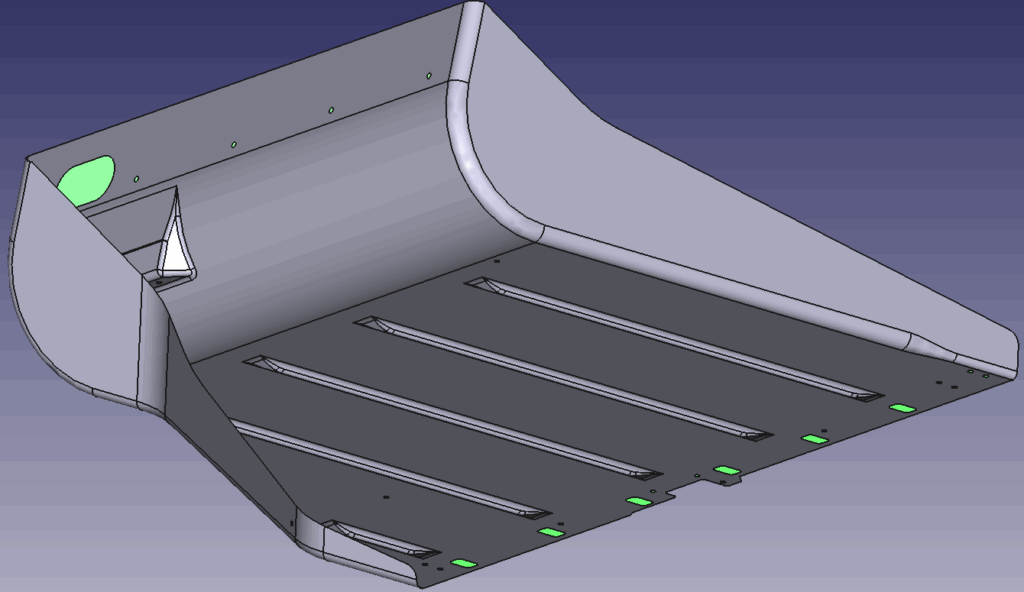

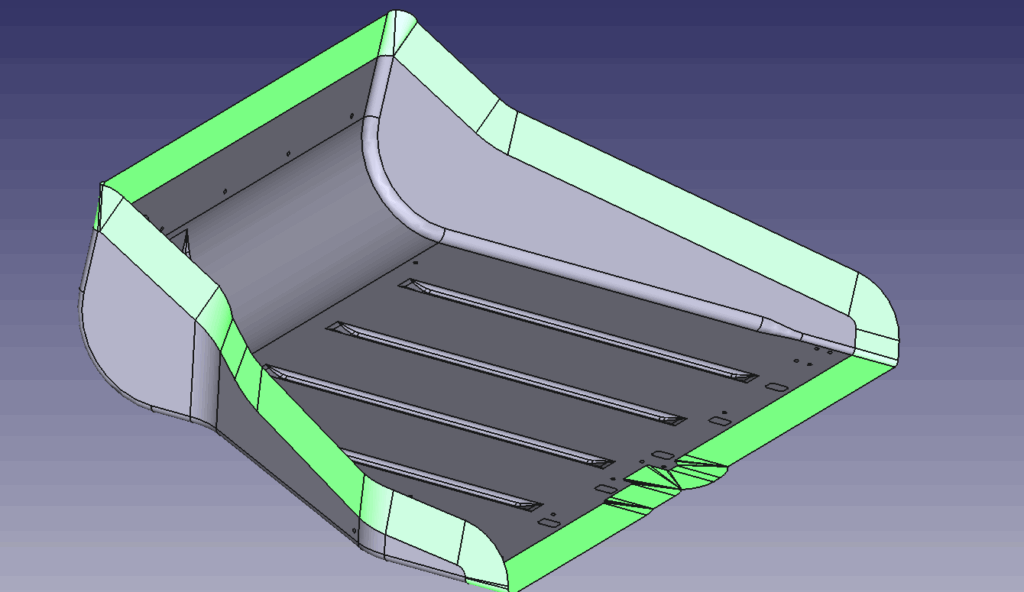

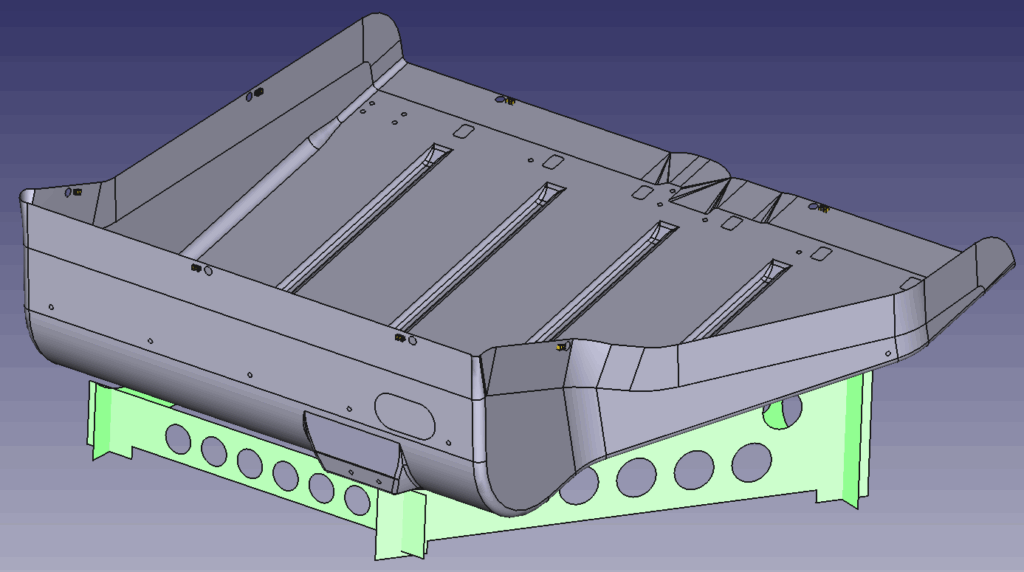

Introducing our patented ‘Generative Molding’ feature

Generate instant tooling designs ❯❯❯❯❯

Experience our unique patented technology Create instant precision tooling from a component STEP file.

Plyable’s specialist engineers, mathematicians and computer scientists have designed this leading-edge feature enabling you to receive fast quality tooling complete with full technical instructions and a pattern.

Phase 1

Calculate molded surface

Phase 2

Fill cutouts and holes and create runoff

Phase 3

Extrude boundary to mold box and fill faces

Phase 4

Add backing structure & LT holes

Plyable Insights

Plyable attends MIA CTS – The Motorsport Engineering and Technology Show

Mid-October 2025 saw the sales and marketing team visit Silverstone for the…

Get in touch for a free consultation

Complete our contact us form for a rapid response:

Please note that buy completing this form you agree to be contacted by our sales team and your email will be automatically added to our marketing communications list which you can opt out of at any time.

Or book a call in with our sales support team today:

For a completely free discussion, to gain a better understanding how we can help your teams specific needs or to talk through your quote, speak to our dedicated and supportive team.

Discover our AI-driven manufacturing software.

Speed up your composite and metallic mold and part manufacturing, without compromising on quality.

Simply upload your CAD file via our Plyable Portal to receive an instant quote:

Bank Grade Security

Wordwide Delivery

Stay connected.

Follow us on LinkedIn or sign up to our marketing newsletter.

- See our latest projects first

- Connect with our expert team

- Access deals and promotions

”Great communication, the website was very good and allowed easy sharing of files & communication.

The team were a great help and ultimately designed us a fantastic tool”

-Automotive client, July 2025