Exploring Innovation at the Motorsport Industry Association’s CTS Show at Silverstone

On Tuesday 15th October, members of the Plyable team attended the Motorsport Industry Association’s (MIA) CTS – The Motorsport Engineering and Technology Show, hosted at the legendary Silverstone Circuit. As one of the UK’s premier motorsport venues, Silverstone provided the perfect backdrop for a showcase of cutting-edge motorsport technology, advanced materials, and engineering innovation that continue to drive the performance sector forward.

Representing Plyable were Josh, from our Business Development team, and myself, Kristy McMillan in Marketing. The event brought together a remarkable cross-section of the UK’s motorsport engineering ecosystem, from pioneering manufacturers to innovative support partners, all under one roof. With three halls full of exhibitors, the show offered an incredible opportunity to explore the latest trends, composite materials, additive manufacturing solutions, and design methodologies shaping the future of F1, endurance racing, and other elite motorsport disciplines.

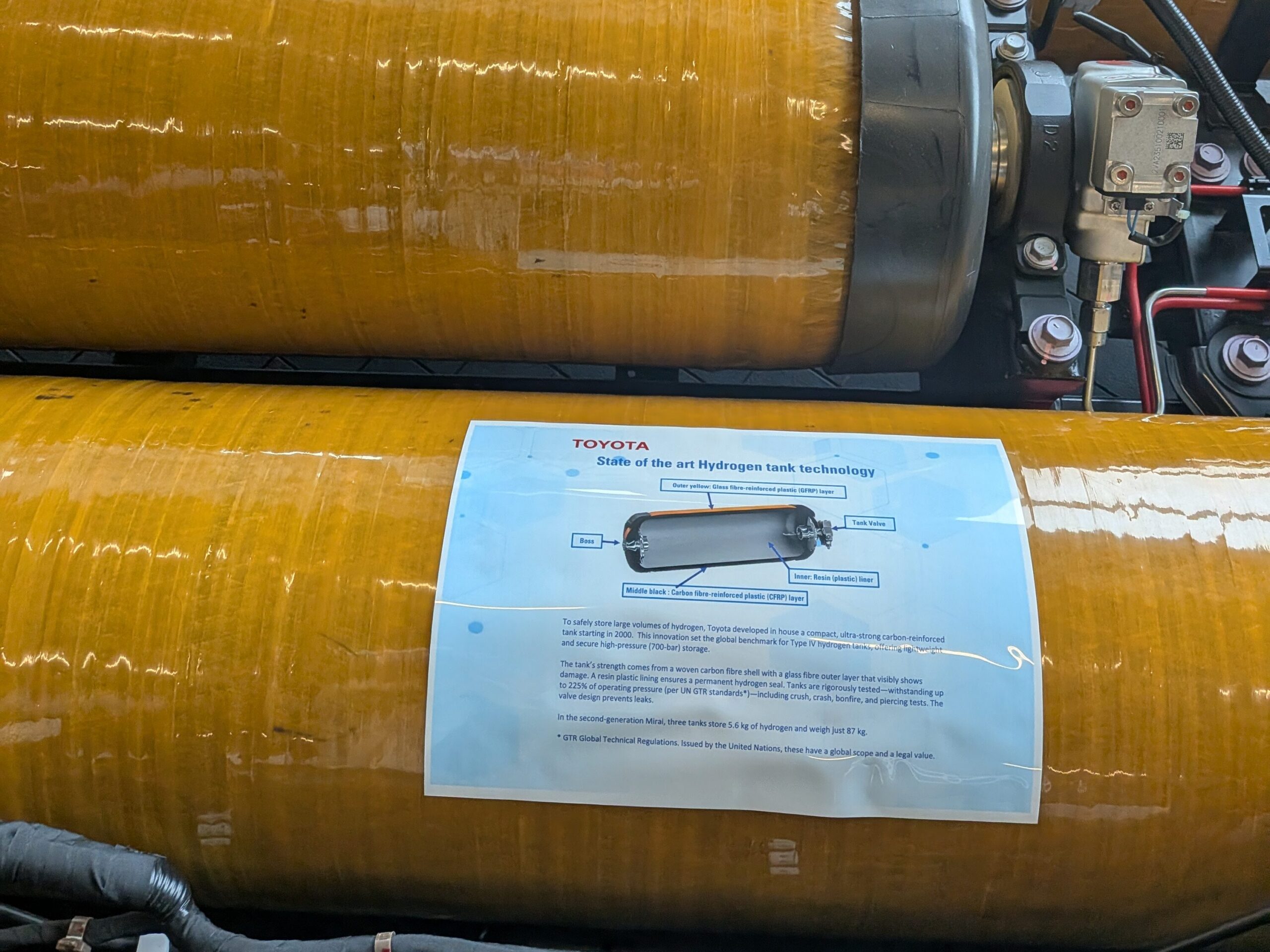

One of the standout exhibits came from Toyota, who showcased their hydrogen-powered engine concept. While hydrogen propulsion has been discussed in motorsport for several years, seeing it up close and speaking directly with one of Toyota’s representatives was genuinely eye-opening and inspiring.

Toyota shared how this zero-emission powertrain is already making its way into the consumer market, with around 200 vehicles currently on the road. Although infrastructure remains a challenge (with only four hydrogen refuelling stations currently available in the UK), Toyota’s holistic approach impressed us. They’ve considered not only performance and efficiency but also sustainability across the entire product lifecycle, including the recycling of hydrogen cylinders into reusable automotive components. It’s an exciting glimpse into how motorsport innovation can accelerate the transition toward a greener, more sustainable automotive industry.

RYSE 3D: Redefining Carbon Fibre Manufacturing

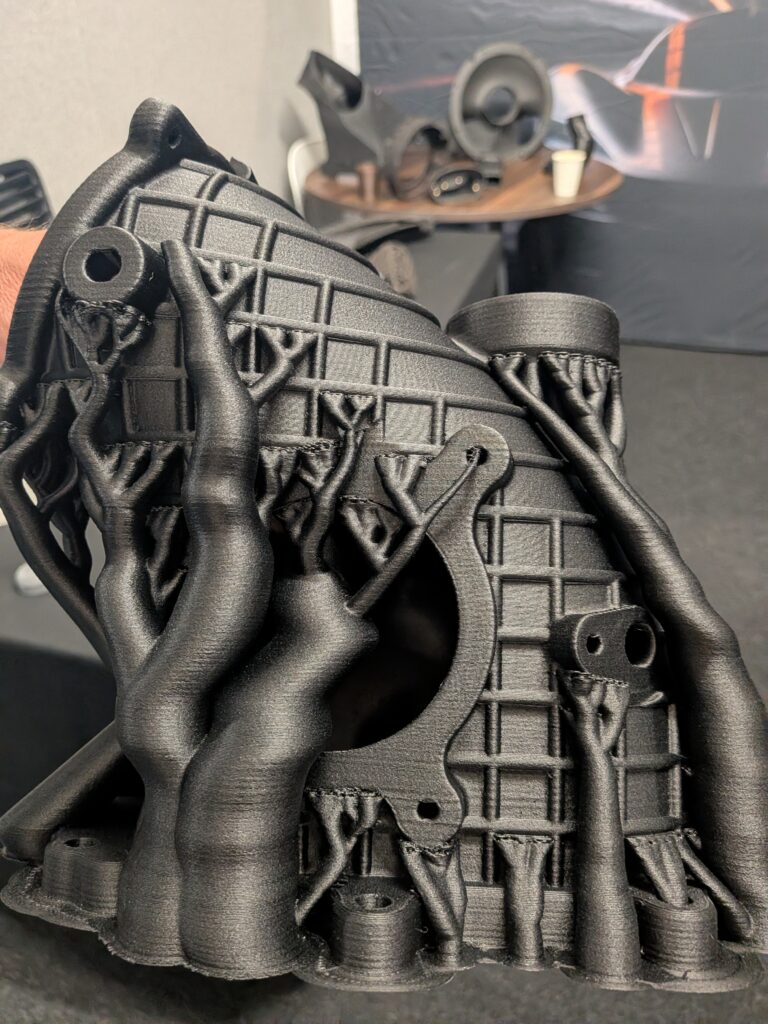

Another highlight of the day was discovering RYSE 3D, a company producing some of the most advanced carbon fibre components we’ve seen to date. Their display included two parts made from the same carbon polymer material, yet exhibiting completely different forms and elasticities – a fascinating demonstration of how adaptable modern composite manufacturing has become.

One piece that particularly caught our attention was a black carbon fibre oil sump capable of holding oil directly without any additional lining, a remarkable feat of material science and precision engineering.

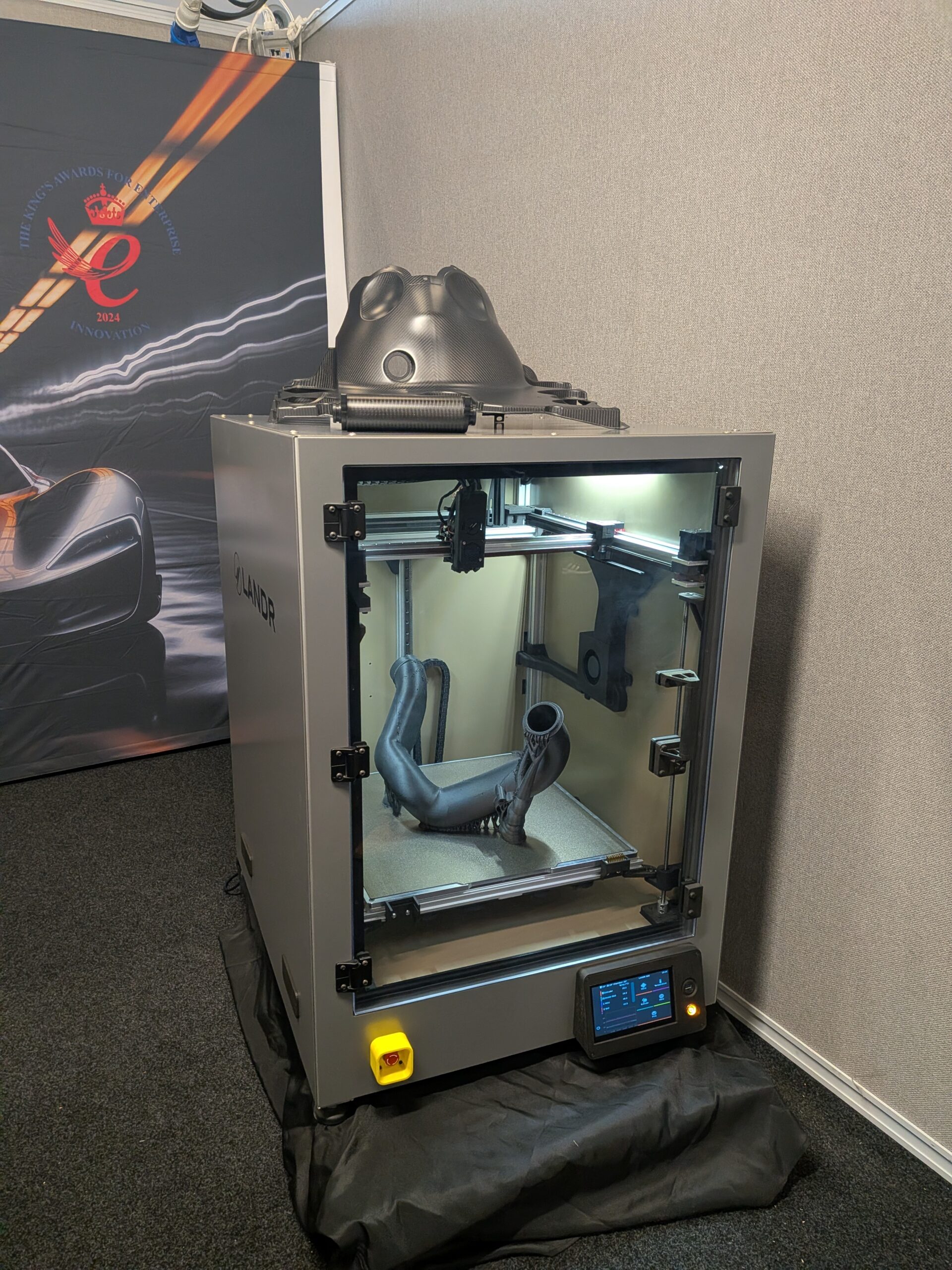

We also learned more about Landr 500, RYSE 3D’s subsidiary brand focused on delivering accessible and cost-effective industrial 3D printing machines with a proudly British manufacturing ethos. Their commitment to democratizing industrial additive manufacturing aligns perfectly with the industry’s broader shift toward agile, on-demand production which is something we at Plyable are equally passionate about.

Find out more about RYSE 3D and LANDR here

Carbon: Bridging Additive Manufacturing and Motorsport

We also had the chance to meet with Carbon, a global leader in additive manufacturing technology. Many will recognize Carbon for their collaboration with Adidas, where they’ve collaborated and co-developed high-performance elastomeric resin soles for footwear.

Now, Carbon is leveraging this same expertise to support motorsport teams across F1 and NASCAR, helping them produce cost-efficient yet high-performance composite components through advanced 3D printing. Their scale, R&D investment, and innovative material science position them as a key player in the next wave of motorsport manufacturing.

You can read more about their work in motorsport here:

Creating Engine Envy with Evans Motorsport Performance

Reflecting on CTS 2025

The MIA CTS Show at Silverstone proved to be an invaluable experience for the Plyable team. From sustainable powertrains to composite partnerships and additive breakthroughs, the event highlighted innovation and collaboration are key to propelling forwards. We also witnessed how these advancements are influencing the future of engineering and manufacturing more broadly. After making some really valuable contacts so we will definitely be looking to return next year.

We left inspired by the creativity, precision, and ambition on display. We are even more motivated to continue helping our partners accelerate their product development through smarter, faster composite tooling solutions. For further information on how we can support motorsport >

About Plyable

At Plyable, we’re redefining the way composite tooling and parts are designed and manufactured. Our AI-driven platform automates the design and quoting process. This enables engineers and manufacturers to go from CAD to product faster than ever before. Our process does not compromise on quality or performance as we work with our partners to ensure high quality product.

Trusted by leading motorsport, aerospace, and marine manufacturers, Plyable helps teams push the boundaries of design and production. Precision-engineering coupled with state of the art machine-learning technology. Our goal is to ensure clients design right, every time. From quoting, through to sourcing suppliers, and from auto-generation of molds through to engineering project management, production and logistics. Our method has your project covered.

Stay connected.

Follow us on LinkedIn or sign up to our marketing newsletter.

- See our latest projects first

- Connect with our expert team

- Access deals and promotions

”Great communication, the website was very good and allowed easy sharing of files & communication.

The team were a great help and ultimately designed us a fantastic tool”

-Automotive client, July 2025

Wish to speak to us about a project?

Fill out our contact us form, we will always aim to get back to you on the same working day

Book in directly with Sales

info@plyable.com | 01865 686164

Joshua England – Global Sales support